Looking for a drill rig? The wrong choice can cost you time and money. Knowing what to look for is key to successful projects.

When buying a drill rig, consider your project type, rig specifications, site conditions, new vs. used options, long-term costs, reliability, safety, and manufacturer support to ensure a smart investment.

Choosing the right drill rig isn’t just about specs—it’s about long-term value. From desert durability to after-sales support, smart buyers look beyond the price tag. I have seen clients make costly mistakes by overlooking key details. As a factory owner at Hardrock, I understand that a drill rig is a major investment. It needs to work reliably, endure tough conditions, and be fully supported throughout its lifespan. Let's look at the crucial things you must consider.

What kind of drilling project are you undertaking, and how does it affect the type of rig you need?

Choosing the wrong rig for your project? This can lead to massive cost overruns. Understand your specific project needs first.

Your drilling project type directly dictates the rig needed. Water wells, geotechnical surveys, and mining exploration each require different rig types, power, and depth capabilities.

The very first question I ask any potential client is, "What are you drilling for?" This might seem basic, but it is fundamental. A water well drilling rig1, like those Mohammed Al-Rahman buys for his projects in Dubai, is designed for different tasks than a mining exploration drilling rig2. For example, water well drilling often involves softer formations and a need for large diameter holes, while mining exploration rigs must handle hard rock and deep core sampling. Geotechnical drilling rigs are for site investigation, usually at shallower depths, requiring precise sampling. Foundation drilling rigs, on the other hand, need high torque for large-diameter piles. At Hardrock, we offer a range of products because we understand these differences. A light, portable rig would fail miserably trying to drill a deep oil and gas well. Similarly, a heavy-duty mining rig would be overkill and inefficient for small-scale water supply. Matching the rig's design, power, and drilling method to your specific project needs—whether it is for a rural water supply or a major mining venture—is the first step to ensuring success and profitability.

What types of drill rigs are available, and which one is best suited for your application?

Confused by the many drill rig types? Picking the wrong one wastes time and money. Learn your options to choose wisely.

Many rig types exist: water well, geotechnical, geothermal, foundation, mining exploration, and oil/gas. Each is best for specific applications based on geology, depth, and hole size.

Once you know your project, you can explore the types of rigs available. As a manufacturer of drilling rigs, I know that each type has its unique design and purpose.

- Water Well Drilling Rigs: Designed for drilling boreholes for water extraction. They often use rotary or DTH (Down-The-Hole) hammer methods and prioritize speed and large diameter.

- Geotechnical Drilling Rigs: For soil investigation, sampling, and in-situ testing. They prioritize accuracy and sample quality.

- Geothermal Drilling Rigs: Built to drill deep boreholes for geothermal energy systems. They need to handle various geological formations.

- Foundation Drilling Rigs: Used for civil engineering, constructing piles for building foundations. They need high torque for large diameters.

- Mining Exploration Drilling Rigs: Crucial for mineral exploration, often performing core drilling to retrieve rock samples. These rigs need high depth capacity and precision.

- Oil and Gas Drilling Rigs: The largest and most complex, designed for extremely deep wells.

At Hardrock, we specialize in water well, geotechnical, geothermal, foundation, and mining exploration rigs. The "best" rig is the one that efficiently and safely meets your project's specific demands, considering the ground conditions and required hole characteristics. For example, Mohammed Al-Rahman, my typical client, often purchases both water well and foundation drilling rigs, which highlights the varied needs even within one company.

What key technical specifications should you evaluate before buying a drill rig?

Buying a rig without knowing key specs? This leads to poor performance. Understand the numbers that matter.

Key technical specifications to evaluate include drilling depth, hole diameter, engine power, rotary torque, pull-up/pull-down force, and rotary speed. These ensure the rig meets job demands.

After identifying the rig type, you must dive into the technical specifications. These numbers tell you what the machine can truly do.

| Specification | Importance |

|---|---|

| Drilling Depth | Max depth the rig can reach. Must exceed your project's deepest requirement. |

| Hole Diameter | Range of hole sizes it can drill. Crucial for water wells or large foundation piles. |

| Engine Power (HP) | The power source. More power means better performance in tough conditions. |

| Rotary Torque | The rotational force applied to the drill bit. Higher torque is needed for hard rock or large diameters. |

| Pull-up/Pull-down Force | How much force the rig can apply upwards (to pull rods) and downwards (to push the bit). |

| Rotary Speed | How fast the drill head rotates. Different speeds suit different formations and drilling methods. |

| Mud Pump/Air Compressor Flow | Capacity of auxiliary equipment, vital for flushing cuttings. |

These specs determine if a rig is capable of your job. For example, for a mining exploration project requiring deep core samples in hard rock, high rotary torque and strong pull-up force are critical. For a water well, efficient mud pump flow and suitable hole diameter capabilities are key. At Hardrock, we provide detailed specifications for all our rigs and can help you interpret them to ensure a perfect match for your needs.

How do your drilling site’s terrain and geological conditions influence your rig selection?

Ignoring site conditions? Your drill rig won't perform efficiently. Match your rig to the ground.

Terrain and geology heavily influence rig selection. Rugged terrain demands crawler-mounted rigs3, while hard rock requires specific drilling methods4 and higher power.

The operating environment is a major factor. Your drilling site’s terrain and underlying geology directly affect the rig’s mobility and drilling method suitability. For example, if your project is in a remote, mountainous area with rough, uneven ground, a truck-mounted rig might struggle to access the site. A crawler-mounted drill rig, with its superior stability and off-road capability, would be a much better choice. We often recommend our crawler rigs for African and Middle Eastern regions where terrain can be very challenging. Beyond mobility, the geological conditions dictate the drilling method. Are you drilling in soft soil, fractured rock, or solid granite? Each requires different tooling and drilling techniques. For hard rock formations, you might need a rig capable of DTH hammer drilling5 or diamond core drilling with specialized drill bits. For soft ground, rotary drilling with mud circulation might be sufficient. Mohammed Al-Rahman, operating in the UAE, needs rigs that can handle the harsh desert conditions and varied geology, from sand to consolidated rock. This means considering aspects like dust protection, engine cooling systems, and robust undercarriages to withstand the environment.

Should you buy a new or used drill rig, and how do you weigh the costs and risks?

New or used rig dilemma? Each has clear pros and cons. Make an informed choice for your business.

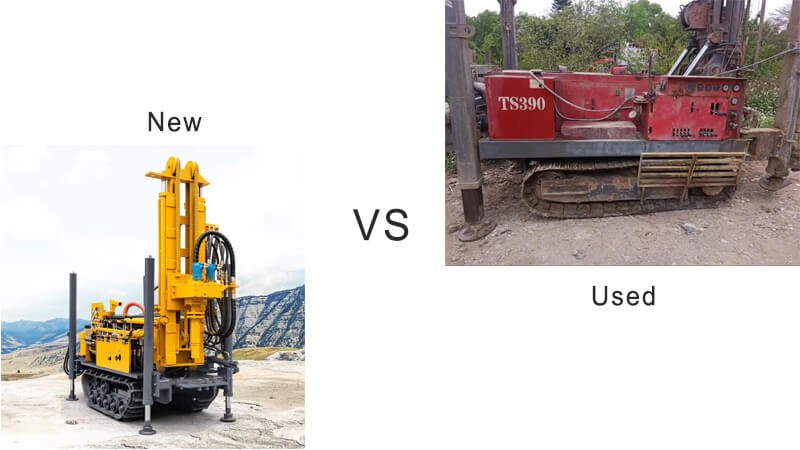

New rigs offer warranty, latest tech, and full support. Used rigs can save money upfront but come with higher risks of unknown issues, less support, and potential breakdowns.

This is a common question. As a factory owner, I naturally advocate for new equipment, but I understand the appeal of a lower upfront cost.

New Drill Rigs:

- Pros: Full manufacturer warranty, latest technology, peak performance, access to comprehensive after-sales support, spare parts availability guaranteed, typically higher safety standards. You know the full history.

- Cons: Higher initial investment.

Used Drill Rigs:

- Pros: Lower initial purchase price, immediate availability sometimes.

- Cons: No warranty (or limited), unknown maintenance history, potential for hidden problems, older technology, finding spare parts might be difficult, higher risk of downtime, potentially higher long-term maintenance costs.

While a used rig might seem like a bargain, the long-term costs of repairs, lost productivity due to breakdowns, and lack of support can quickly outweigh the initial savings. For companies like Mohammed Al-Rahman's, who prioritize reliability and after-sales service, the investment in a new rig often pays off by ensuring consistent operation and minimizing expensive downtime. My advice is always to consider the true cost of ownership, not just the purchase price.

What are the true costs of owning and operating a drill rig over time?

Rig purchase is just the start. Hidden costs can quickly drain profits. Know the full financial picture.

True costs include initial purchase, fuel, lubricants, maintenance, spare parts, consumables, operator wages, training, insurance, and potential downtime, which all impact long-term profitability.

Many buyers focus only on the purchase price. But a drill rig is a working asset, and its true cost extends far beyond the initial transaction. As a manufacturer, I encourage my clients to look at the total cost of ownership.

- Initial Purchase Price: This is obvious, but it is just one piece.

- Fuel and Lubricants: A significant ongoing expense, especially for powerful rigs running many hours.

- Consumables: Drill bits, drill rods, mud, drilling fluids – these are constantly used and replaced.

- Maintenance and Repairs: Regular preventative maintenance extends lifespan. Unexpected breakdowns require parts and labor. This is where reliability and spare parts availability from Hardrock become crucial.

- Spare Parts: Having critical spares on hand minimizes downtime. My typical customer, Mohammed, faces pain points with long lead times for spare parts, which highlights this as a major cost concern.

- Labor Costs: Wages for skilled operators and maintenance staff.

- Training: Investing in proper training for your team ensures efficient and safe operation, reducing errors and wear.

- Insurance: Protecting your valuable asset.

- Transportation: Moving the rig between sites.

- Downtime Costs: When the rig is not working, it's not making money. This is the most damaging "hidden" cost.

Understanding these elements allows for better budget planning and a clearer picture of profitability.

How reliable is the rig, and are spare parts and maintenance support easily available?

Rig breaks down often? Lack of parts stops work. Reliability and parts availability are critical for consistent operation.

Rig reliability ensures continuous operation. Easy access to spare parts and prompt maintenance support from the manufacturer are vital to minimize costly downtime and extend the rig's lifespan.

I cannot stress enough the importance of reliability and support. An unreliable rig is a liability, not an asset. At Hardrock, our entire manufacturing process, from design to assembly, focuses on building robust and reliable drilling rigs that can withstand the demands of B2B projects in diverse environments. This is a testament to our 15 R&D personnel and our 3 production lines. But even the best machines need parts and service. Mohammed Al-Rahman's biggest pain points include long lead times for spare parts delivery and language barriers in technical support. This is why when you deal with us, we ensure transparency about our spare parts availability and logistics. We aim to make spare parts easily accessible to our global clients in Africa, the Middle East, Southeast Asia, North America, and Europe. We also offer clear technical documentation and responsive support. A reliable machine, coupled with readily available spare parts and effective maintenance assistance, means more uptime for your operations and less frustration.

Does the rig meet all safety standards, and is your team qualified to operate it?

Safety comes first. Unsafe rigs or untrained staff risk lives and projects. Prioritize standards and training.

Rigs must meet strict international safety standards to protect personnel. Your team must also be fully qualified and trained to operate the equipment safely and efficiently.

Safety is paramount in the drilling industry. My team and I understand this deeply. Every drill rig we produce at Hardrock is designed and manufactured with safety in mind, adhering to relevant international standards. You should always verify the safety certifications of any rig you consider. This includes things like emergency stop buttons, guarding around moving parts, pressure relief valves, and clear operational controls. But a safe rig is only one part of the equation. Your operating team must be fully qualified and well-trained. A powerful machine in untrained hands is a huge risk. We often provide technical training support, either at our factory or on-site, to ensure operators understand how to use and maintain our equipment safely. Mohammed Al-Rahman, for example, often brings his technical team for pre-purchase inspections and values comprehensive technical training. Investing in operator training not only prevents accidents but also leads to more efficient operation and less wear and tear on the machine.

How important is the manufacturer’s reputation and the quality of their after-sales service?

Manufacturer reputation is vital. Bad service sinks projects. Choose wisely for long-term success.

A manufacturer's reputation and quality after-sales service are crucial for long-term value. They provide reliability, support, parts, and training, ensuring your investment performs over time.

This is exactly my core insight: "The best exploration rigs aren’t just built—they’re backed." The manufacturer's reputation is a reflection of their commitment to quality, integrity, and support. At Hardrock, with our 8000 square meter factory and our B2B wholesale model, our reputation is everything. Quality after-sales service is not an add-on; it is an integral part of the product. Mohammed Al-Rahman is pragmatic and relationship-oriented; he values long-term partnerships. He is willing to pay a premium for proven quality and comprehensive technical documentation. What does good after-sales service look like? It means responsive technical support, efficient spare parts logistics, clear warranty terms, and the availability of training programs. If a manufacturer stands behind their product with excellent service, it gives you peace of mind and reduces the overall risk of your investment. Always look for evidence of consistent support, not just promises.

What should you consider regarding shipping, installation, and operator training?

Rig delivery isn't simple. Ignoring logistics causes delays and costs. Plan shipping, installation, and training ahead.

Consider detailed shipping logistics, professional installation support, and comprehensive operator training. These steps ensure your rig arrives safely, is set up correctly, and is operated proficiently.

The journey of a drill rig from our factory floor in China to your drilling site involves several critical steps that demand careful consideration.

- Shipping: As a factory, we handle significant international shipping to regions like Africa, the Middle East, North America, and Europe. You need to consider freight costs, transit times, and customs clearance procedures. Mohammed Al-Rahman specifically mentions complex customs clearance as a pain point. A good manufacturer will help you navigate these complexities and offer advice on the most efficient shipping methods.

- Installation: While many rigs can be assembled by a competent technical team, complex rigs might benefit from professional installation support provided by the manufacturer. This ensures correct setup and initial testing.

- Operator Training: This is paramount. Even the most advanced rig is useless without skilled operators. We offer training programs that cover operation, basic maintenance, and troubleshooting. This training can be done at our facility or, if feasible, on-site at your location. Proper training directly impacts safety, efficiency, and the longevity of the equipment. Neglecting any of these steps can lead to costly delays or operational issues.

What are the most common mistakes buyers make when purchasing drill rigs—and how can you avoid them?

Avoid common buyer mistakes. They cost time and money. Learn from others to save your project.

Common mistakes include buying based on price alone, neglecting after-sales support, ignoring site-specific needs, and insufficient operator training. Avoid these by thorough research and vetting.

From my years of experience selling drilling rigs globally, I've seen some recurring mistakes. Avoiding them saves you significant headache and money.

- Buying Solely on Price: The cheapest rig is rarely the best value. It often means compromised quality, poor support, and higher long-term costs.

- Ignoring After-Sales Support: Lack of spare parts or technical assistance cripples operations. Mohammed Al-Rahman always looks for comprehensive technical documentation and responsive service.

- Not Matching Rig to Project/Site: A rig that works well in one geology will fail in another. Always consider your specific ground conditions and project requirements.

- Neglecting Operator Training: An untrained operator can damage the machine, cause accidents, and reduce efficiency.

- Failing to Budget for True Costs: Forgetting about fuel, maintenance, consumables, and downtime.

- Not Verifying Manufacturer Claims: Always check references, visit the factory if possible, and scrutinize specifications.

- Poor Communication: Unclear expectations between buyer and seller lead to misunderstandings.

To avoid these, do your homework. Communicate clearly, ask tough questions, and prioritize long-term value over short-term savings.

What should be on your final checklist before closing the deal on a drill rig?

Ready to buy? Don't miss crucial steps. Use a final checklist to secure your investment.

Your final checklist should include verifying specifications, warranty, service terms, spare parts availability, training plans, and confirming all payment and delivery details.

Before you sign on the dotted line, run through this final checklist. This ensures all critical aspects are covered and you are making a confident, well-informed decision.

- Confirm all technical specifications: Double-check that the rig's capabilities (depth, diameter, power, torque) exactly match your project requirements.

- Review warranty terms: Understand what is covered, for how long, and the process for claims.

- Finalize after-sales service agreement: Confirm technical support availability, response times, and communication methods.

- Agree on a spare parts package: Discuss essential wear-and-tear parts and ensure a clear understanding of ongoing parts availability and logistics.

- Confirm operator training arrangements: Get details on who, where, when, and what is covered in the training.

- Verify shipping and installation details: Clarify responsibilities, timelines, and costs.

- Review payment schedule and terms: Ensure everything aligns with your financial plan.

- Check safety certifications: Confirm that the rig meets all relevant safety standards.

- Read the full contract carefully: Make sure all agreed-upon points are explicitly stated.

This comprehensive approach, focusing on long-term value, is how smart buyers like Mohammed Al-Rahman secure reliable equipment for years of profitable operation.

Conclusion

Choosing a drill rig means looking beyond the price tag. Focus on project fit, specs, site conditions, long-term costs, reliability, safety, and strong manufacturer support for true value.

-

Learn about water well drilling rigs and their specific applications to make informed decisions for your drilling projects. ↩

-

Discover the unique features of mining exploration drilling rigs to ensure you select the right equipment for deep core sampling. ↩

-

Exploring the benefits of crawler-mounted rigs can help you choose the right equipment for challenging environments. ↩

-

Learning about various drilling methods can enhance your knowledge and improve your drilling strategy in hard rock conditions. ↩

-

Learn about DTH hammer drilling techniques and their applications in hard rock formations for effective drilling. ↩