Facing water scarcity? Finding reliable water sources can be a real challenge. Understanding drilling methods is key to unlocking your water supply.

Water well drilling uses various methods, including cable tool, rotary (mud and air), and down-the-hole hammer, each suited for different geological conditions. Choosing the right method ensures efficient, sustainable water access.

After years of experience in manufacturing drilling equipment at Hardrock, I have seen first-hand how understanding these methods can change a project's outcome. My insights, gained from working with countless clients worldwide, show that the right choice leads to better water output, longer equipment life, and lower operational costs. Let's explore the common techniques.

What Is Cable Tool Drilling and How Does It Work?

Worried about complex drilling? Cable tool drilling is one of the oldest methods, surprisingly effective and simple to understand, offering a dependable way to get water.

Cable tool drilling involves repeatedly dropping a heavy bit to crush and loosen rock, then removing cuttings with a bailer. This percussive method is slow but highly effective in consolidated formations and for well development.

How Cable Tool Drilling Operates

From my perspective, cable tool drilling is like a very large, slow hammer. The process starts with a heavy drill bit attached to a cable. A mast on the rig lifts this cable and then lets it drop. The weight of the bit crushes the rock at the bottom of the borehole. After several drops, the crushed rock, which we call cuttings, mixes with water to form a slurry. The operator then pulls out the drill bit and lowers a device called a bailer. The bailer is a long pipe with a check valve at the bottom. It collects the slurry and brings it to the surface. This entire cycle repeats. This method is slow. However, it is very precise. We have seen it used effectively in very hard rock formations where other methods struggle. It also allows for detailed examination of rock samples. This helps identify water-bearing zones. For customers like Mohammed in places with varying geology, this steady, reliable method offers a proven path to water, even if it takes more time.

Advantages and Disadvantages of Cable Tool Drilling

From our experience at Hardrock, we know every method has pros and cons.

| Aspect | Advantage | Disadvantage |

|---|---|---|

| Effectiveness | Excellent in hard rock, very accurate for sampling. | Very slow penetration rates. |

| Well Quality | Creates a straight, stable borehole; good for well development. | Less suitable for unconsolidated or collapsing formations. |

| Equipment | Simple, robust machinery; lower initial rig cost. | Requires specialized skill; higher ongoing labor costs due to speed. |

| Environmental | Uses less water; minimal disturbance. | Can be noisy; drill site is active for longer periods. |

This method is known for its durability. My team has found that equipment used in cable tool drilling can last a long time. This is important for clients who prioritize long-term investment.

How Much Does Water Well Drilling Cost Per Foot?

Concerned about drilling costs? Water well drilling expenses vary greatly. Understanding the factors that impact the price per foot helps you budget effectively.

Water well drilling costs per foot depend on factors like depth, geology, drilling method, casing material, and local labor rates. Prices can range from $15 to $60 or more per foot, not including pump and hookups.

Factors Influencing Drilling Costs Per Foot

Based on what I have seen over the years at Hardrock, the "cost per foot" is rarely a fixed number. Many variables change the price.

Depth of Well

The deeper you go, the more it costs. This is because deeper wells need more pipe, more casing, and more time. My team has learned that sometimes, a small increase in depth can lead to a big jump in cost.

Geology of the Area

Drilling through soft sand is much cheaper than drilling through solid granite. Hard rock means slower progress. It also means more wear on drill bits and other tooling. This directly increases operational costs. We at Hardrock design our bits to last. This helps reduce these costs for our customers.

Chosen Drilling Method

As we discuss in other sections, different methods have different operational speeds and equipment needs. Rotary drilling can be faster, but it may require more complex mud systems. Cable tool is slower, but it needs less complex equipment. Each method has its own cost structure. We work to provide the right rig for the job. This helps our clients achieve the most cost-effective solution.

Casing and Screen Materials

The material of the well casing (steel, PVC) and the screen also affects cost. High-quality materials, while more expensive upfront, can prevent problems later. Mohammed, my typical customer, values proven quality. He knows that paying more for quality now saves money later.

Accessibility of the Site

If a drill rig cannot easily reach the site, costs go up. This involves time for site preparation and transport.

Local Regulations and Permits

Sometimes, getting permits adds to the overall cost. These can vary greatly by region.

What Is Rotary Drilling and Why Is It Popular?

Need fast, efficient drilling? Rotary drilling is a modern, widely used technique. It excels at quickly creating boreholes across various ground conditions.

Rotary drilling uses a rotating drill bit to cut rock, with drilling fluid (mud rotary) or compressed air (air rotary) to remove cuttings and stabilize the borehole. Its speed and versatility make it a popular choice for many projects.

The Mechanics of Rotary Drilling

From my vantage point in manufacturing, rotary drilling represents a significant leap forward in drilling technology. Unlike the hammering action of cable tools, rotary drilling involves continuous rotation of a drill bit. This bit cuts and grinds the rock. Simultaneously, a fluid, either drilling mud or compressed air, is pumped down through the drill pipe. This fluid serves two main purposes: it cools the drill bit and carries the rock cuttings back up to the surface. When my team designs our Hardrock rotary rigs, we focus on powerful rotation and efficient fluid circulation. This ensures maximum penetration rate. We make two main types of rotary drilling: mud rotary and air rotary. Mud rotary uses a specialized drilling mud. This mud stabilizes the borehole walls. It also carries cuttings. It is good for softer, unconsolidated formations. Air rotary uses compressed air. It is very fast in hard, dry rock. Many of our customers in places like the Middle East choose our air rotary rigs for their speed and efficiency in dry, hard ground.

Why Rotary Drilling Is So Widely Used

I have observed that rotary drilling is popular for several clear reasons.

Speed

It is much faster than cable tool drilling. This means projects finish sooner. For our B2B customers, time is money. Faster drilling leads to quicker project completion.

Versatility

Rotary rigs can handle a wide range of geological formations. With the right bit and fluid, they can drill through soft clay, sand, or hard rock. This flexibility is a huge advantage for contractors who face diverse ground conditions.

Borehole Stability

With mud rotary, the drilling fluid creates a filter cake on the borehole walls. This helps prevent collapse. This is very important for maintaining a stable well.

Continuous Operation

Unlike cable tool drilling, which requires frequent stops for bailing, rotary drilling is a more continuous process. This smooth operation contributes to its efficiency.

Integration of Technology

Modern rotary rigs, including those we build at Hardrock, integrate advanced controls and automation. This makes them easier to operate and more precise. We also ensure that our rigs are robust. They can withstand the harsh conditions our clients, like Mohammed, face. This ensures long equipment life.

Which Drilling Method Is Best for Residential Water Wells?

Planning a residential well? Picking the best drilling method for your home can be confusing. The right choice ensures a lasting, clean water supply.

The best method for a residential water well depends on local geology, water table depth, and budget. Rotary drilling (mud or air) is often preferred for its speed, while cable tool remains a reliable choice in specific hard rock areas.

Factors for Choosing a Residential Well Method

From my experience, deciding on a drilling method for a home well is a very practical decision. It involves balancing several key factors. My team at Hardrock often consults with clients about their specific needs.

Local Geology

This is perhaps the most important factor. If the ground is mostly sand and gravel, a mud rotary rig works well. It handles unconsolidated formations effectively. If the area has a lot of hard bedrock, an air rotary rig with a down-the-hole hammer or even a cable tool rig might be better. A cable tool rig is slower but very good at drilling through solid rock. It also brings up good samples for identifying water zones.

Water Table Depth

If the water table is shallow, many methods can work. For very deep water, a faster method like rotary drilling becomes more practical to save time and labor costs. Our Hardrock rigs are designed for various depths. This allows customization for specific needs.

Budget

The cost of the drilling equipment, the time it takes, and the casing material all affect the total budget. Rotary drilling can be faster. This often means lower labor costs. Cable tool drilling can have lower upfront equipment costs but higher labor time.

Desired Water Quality

Some methods might be better at preventing contamination from surface water. This is a big concern for residential wells. A properly cased and sealed well is essential, regardless of the method.

Local Regulations

Some areas have rules about well depth, casing type, or even the drilling method. It is important to check these rules.

Our Recommendation for Residential Wells

For many residential applications, I usually suggest a smaller rotary rig, especially an air rotary system. This is because it offers a good balance of speed and efficiency. It works well in most common rock types. However, if the ground is very rocky, or if the homeowner wants the absolute highest quality samples to find water, then a cable tool rig is a good choice. We offer compact, reliable rigs at Hardrock that are well-suited for residential drilling. We also provide the right tooling. This ensures the best result for a home water supply.

What Are the Advantages and Disadvantages of Air Drilling?

Considering air drilling for your project? This powerful method offers unique benefits and challenges. Understanding both helps you make an informed decision.

Air drilling uses compressed air to clear cuttings and cool the bit, offering fast penetration rates in hard, consolidated rock and minimal formation damage. However, it is less effective in unconsolidated or wet formations.

How Air Drilling Works and Its Benefits

From my factory floor at Hardrock, I have observed the rise of air drilling. It has become very popular. This method uses a high-pressure air compressor. This compressor pushes air down the drill pipe. The air serves several important roles. It cools the drill bit. It also removes rock cuttings from the borehole very effectively. The cuttings are blown out of the hole. This process makes the drill bit hit fresh rock faster. The result is rapid penetration rates. This is especially true in hard, dry rock formations. Air drilling also keeps the borehole clean. It creates minimal formation damage. This means the water-bearing zones are not plugged up by drilling mud. For customers like Mohammed in arid regions, the clean borehole and high speed are clear benefits. It helps get water wells online faster. We build rigs capable of high air pressure. We also provide the necessary air compressors and down-the-hole (DTH) hammers. These tools are crucial for effective air drilling.

Challenges and Limitations of Air Drilling

However, air drilling also has its limits. I always advise our clients to consider these.

Not Suitable for All Formations

Air drilling struggles in unconsolidated materials like loose sand or gravel. The borehole can collapse because there is no drilling mud to support the walls. It also faces problems in formations with high water content. If a lot of water enters the hole, the air cannot effectively lift the cuttings. This can slow down or even stop drilling.

Dust Control

When drilling in dry formations, air drilling creates a lot of dust. This needs careful management. Dust can be a health hazard. It also needs equipment to control it.

Equipment Requirements

Air drilling needs powerful air compressors. These compressors must deliver high volume and pressure. This adds to the equipment cost. It also means more fuel consumption. My team at Hardrock focuses on making efficient compressors. This helps reduce operating costs for our clients.

Bit Selection

While fast, air drilling relies on specific types of drill bits, such as DTH hammer bits. The right bit choice is critical for success. We ensure our toolings are top quality for these demanding applications.

Noise

The high-pressure air and the DTH hammer can make a lot of noise. This is a concern in populated areas.

Despite these challenges, when conditions are right, air drilling offers one of the most efficient ways to drill water wells. This is why many of our clients choose it for their specific projects.

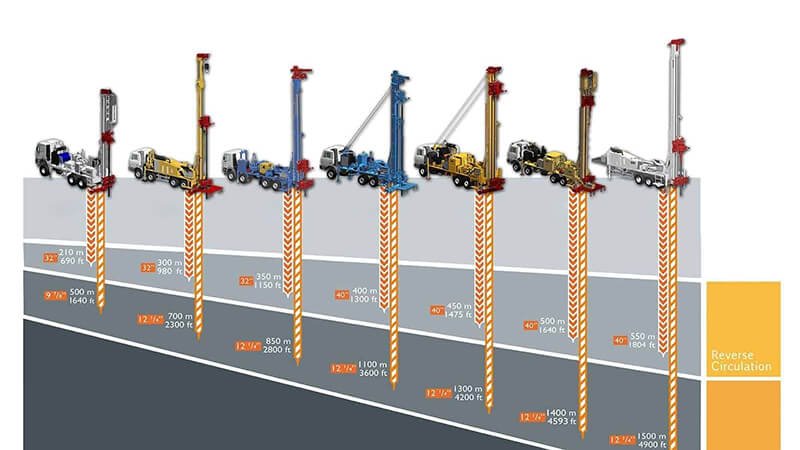

How Deep Should a Water Well Be Drilled?

Wondering how deep your well needs to be? Well depth is critical for reliable water. Knowing the factors ensures a sustainable water source.

Water well depth depends on the local water table, aquifer characteristics, water demand, and regulatory requirements. Wells can range from 50 feet to over 1,000 feet, aiming for a stable, productive water-bearing zone.

Key Factors Determining Well Depth

From my extensive experience in the drilling industry at Hardrock, I can tell you that there is no single answer for well depth. It varies greatly.

Water Table and Aquifer

The most important factor is the depth to the water table and the characteristics of the aquifer. An aquifer is a layer of rock or soil that holds groundwater. You need to drill deep enough to reach a reliable aquifer. Sometimes, a shallow aquifer might be good for a small garden. However, for a steady supply of drinking water, you often need to go deeper to a confined aquifer. These are less affected by surface changes. My team always emphasizes understanding the local geology.

Water Demand

How much water do you need? A residential well for a single family needs less water than a well for a large farm or a commercial project. Higher demand means you might need to drill deeper. This helps access a larger volume of water. It also ensures the well does not run dry easily. Our Hardrock rigs are designed to reach depths needed for various water demands. We offer customization options to suit these different requirements.

Water Quality

Sometimes, shallow groundwater might have poor quality. It might have contaminants from surface activities. Drilling deeper can lead to cleaner, safer water. This is because deeper aquifers are often protected by layers of rock and clay. This acts as a natural filter.

Regulatory Requirements

Local and national regulations often dictate minimum well depths, setbacks from pollution sources, and casing requirements. These rules are in place to protect water quality and ensure sustainable water use. It is always important to check these before starting any project.

Neighboring Wells

Looking at existing wells in the area gives a good idea of typical depths. If many wells nearby are 300 feet deep, then your well will likely need to be similar. This helps predict the expected depth and planning for the right rig.

Choosing the right depth for your water well is a critical step. It directly impacts the well's long-term performance and the quality of the water it provides.

Conclusion

Choosing the right drilling method and depth for your water well project is essential for long-term success. Understanding these techniques ensures efficient water access and optimal equipment performance.