Choosing a drilling rig is confusing with so many types available. The wrong choice leads to wasted money, project delays, and poor performance. Understanding the classifications helps you select the perfect rig.

Drilling rigs are categorized by five main factors: their drilling method, mobility, depth capacity, power system, and specific application. These classifications help match the right equipment to the project, whether it's for water, oil, construction, or scientific research.

I often get this question from new clients, and it's a great one. The huge variety of drilling rigs isn't meant to be confusing. It's actually a good thing. It shows that the industry has developed a specialized tool for nearly every situation you can imagine. From drilling a simple water well in a village to exploring for oil in the deep sea, there is a rig designed specifically for that job. Understanding how they are grouped is the first step to making an informed choice for your project. Let's break down these categories one by one.

How Are Rigs Classified by Drilling Method?

You need to break rock, but different methods exist. Using an inefficient method wears out tools quickly and slows down drilling, costing you time and money. Knowing the main drilling methods helps.

Rigs are classified by how they break rock. The main types are rotary drilling (spinning), percussion drilling (hammering), and top drive drilling (a modern rotary method). Other specialized methods like turbine or PDM drilling use downhole motors for directional drilling.

The method a rig uses to attack the rock is its most basic characteristic. It determines what kind of geology the rig is good for. For example, I sold a rig to a contractor in a mountainous region of Africa. He needed to drill water wells through very hard granite. A standard rotary rig would be too slow. We supplied him with a rig that used a Down-The-Hole (DTH) hammer, a type of percussion drilling. It hammered its way through the rock much faster. Top drive is a more modern version of rotary drilling that many of my clients, like Mohammed in Dubai, prefer. It offers better control and efficiency by rotating the drill string from the top, not from the floor. This allows for longer sections of pipe to be used, which speeds up the whole process. Other methods like turbine and PDM (Positive Displacement Motor) drilling are not rig types, but rather tools placed at the end of the drill string to allow for precise directional drilling, which is common in the oil and gas industry.

| Drilling Method | How It Works | Best For |

|---|---|---|

| Rotary Drilling | A rotating drill bit grinds the rock. | Soft to medium-hard rock, oil & gas. |

| Percussion Drilling | A hammering action chips and shatters the rock. | Very hard, brittle rock. |

| Top Drive Drilling | Rotates the drill string from a motor at the top. | Most modern applications, deep wells. |

| PDM / Turbine | A downhole motor spins the bit independently. | Directional and horizontal drilling. |

How Does Mobility Define a Drilling Rig?

Your project site might be remote or require moving the rig often. A stationary rig is useless if you can't get it there, or if it takes weeks to move between holes.

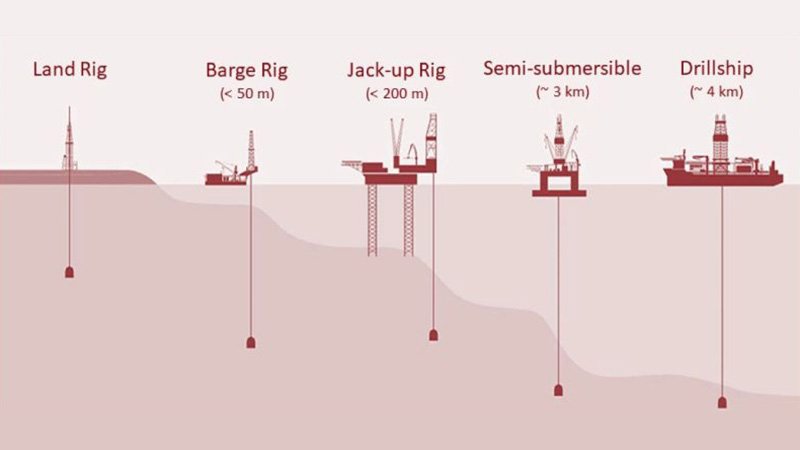

Mobility classification is based on how the rig moves. Land rigs can be truck-mounted, crawler-type, or trailer-mounted for easy transport. Offshore rigs are giant structures like jack-up platforms, semi-submersibles, or drillships that operate on the sea.

How you get the rig to the site is a huge factor. For many of my customers, speed is everything. A contractor doing geotechnical investigations might need to drill dozens of holes across a large construction site. For him, a truck-mounted rig from Hardrock is perfect. He can drive it to a spot, drill a hole, and move to the next one in just a few hours. If the ground is very soft or uneven, a crawler-type rig with tracks is better. It can navigate rough terrain where a truck would get stuck. On the other end of the scale are offshore rigs. These are massive engineering feats. A jack-up rig stands on legs on the seabed in shallow water. For deeper water, a semi-submersible platform floats and is held in place by huge anchors. For the deepest and most remote locations, a drillship, which is a massive ship with a drilling rig in the middle, is used. The choice completely depends on the location and logistics of the project.

| Rig Category | Mobility Type | Typical Use Case |

|---|---|---|

| Land Rig | Truck-mounted, Crawler-type, Trailer-mounted | Water wells, mining, construction, geotechnical |

| Offshore Rig | Jack-up, Semi-submersible, Drillship | Oil & gas exploration in oceans and seas |

What Does a Rig's Depth Rating Really Mean?

You have a target depth to reach for your well. Using a rig that's too weak won't reach the target. Using one that's too powerful is an expensive waste of money.

A rig's depth rating indicates the maximum depth it can safely and efficiently drill. Rigs are categorized as light-duty (to 1500m), medium-duty (1500–3000m), heavy-duty (3000–4500m), and ultra-heavy-duty (over 4500m), based on their hoisting capacity.

A rig’s capacity is about more than just depth; it’s about power, specifically lifting power. The deeper you drill, the longer and heavier the drill string becomes. The rig's hoisting system must be able to lift this incredible weight. I remember a client who tried to save money by using a medium-duty rig for a deep geothermal well. The hoisting system wasn't rated for the weight of the long drill string, and it failed. It was a very costly lesson in matching capacity to the job. Light-duty rigs are perfect for most water wells and geotechnical work. Medium-duty rigs handle deeper water wells and some shallow oil and gas. Heavy-duty and ultra-heavy-duty rigs are the workhorses of the oil and gas industry, designed to drill miles into the earth’s crust. Choosing the right capacity is a critical balance between capability and cost.

| Rig Class | Typical Depth Capacity | Common Applications |

|---|---|---|

| Light-duty | up to 1500 m | Water wells, geotechnical, shallow geothermal |

| Medium-duty | 1500–3000 m | Deep water wells, shallow oil & gas |

| Heavy-duty | 3000–4500 m | Standard oil & gas, deep geothermal |

| Ultra heavy-duty | 4500 m + | Deep-water exploration, complex wells |

How Do Different Power Systems Affect Rig Operations?

A drilling rig needs a massive amount of power to function. The wrong power system can be inefficient, unreliable, or very difficult to maintain in a remote location.

Rigs are powered in several ways. Mechanical rigs use diesel engines and clutches directly. Electric rigs (SCR or VFD) use diesel generators to power electric motors for more precise control. The choice depends on the need for control, efficiency, and maintenance capabilities.

The power system is the heart of the rig. The simplest type is a mechanical drive rig, where diesel engines are connected directly to the equipment through clutches and chains. These are rugged and relatively easy to fix, which is why I often recommend them for projects in very remote areas with limited technical support. However, the modern standard is the electric rig. Here, diesel engines run large generators to produce electricity. This electricity then powers electric motors that run the hoisting and rotating systems. This setup gives the driller incredibly precise control over speed and torque. There are two main types of electric rigs: SCR and VFD. VFD (Variable Frequency Drive) is the more advanced technology, offering the best performance and efficiency. A pragmatic buyer like Mohammed always prefers VFD rigs for their reliability and the detailed operational data they provide, which helps in maintaining the equipment for the long term.

| Power System | Control Precision | Maintenance Complexity |

|---|---|---|

| Mechanical | Low | Low (easier to fix) |

| Electric (SCR) | High | High (requires specialists) |

| Electric (VFD) | Very High | High (requires specialists) |

Why Are Rigs Specialized for Different Applications?

You know what you need to drill for, like water, oil, or foundations. But using a generic rig for a specific job is inefficient and can even be unsafe or damage the final product.

Rigs are highly specialized for their purpose. Oil and gas rigs are built for depth and pressure control. Water well rigs prioritize mobility and clean drilling. Geotechnical rigs focus on precise sample collection. Each type has features optimized for its specific task.

This is where all the other classifications come together. A rig is ultimately defined by its job. At my company, Hardrock, we build many types of rigs because our customers have many different jobs to do. For example, a water well rig must be mobile and designed to prevent contamination of the water source. An oil and gas rig, on the other hand, is all about managing extreme pressure deep underground and must have a massive blowout preventer (BOP) for safety. A geotechnical rig is smaller and designed for one thing: carefully collecting undisturbed soil and rock samples for analysis. A foundation piling rig drills wide, not necessarily deep, holes to be filled with concrete for building supports. Even mining rigs are specialized, designed to quickly drill many blast holes. This specialization ensures that the rig has the exact features needed to do its job safely, efficiently, and cost-effectively.

| Application | Key Feature | Primary Goal |

|---|---|---|

| Oil & Gas | High pressure control (BOP) | Extract hydrocarbons safely |

| Water Well | Mobility, cleanliness | Access clean groundwater |

| Geotechnical | Precise sample collection | Analyze ground conditions |

| Foundation Piling | Large diameter drilling | Create support for structures |

| Mining | Speed, durability | Drill holes for explosives or exploration |

Conclusion

The many types of drilling rigs ensure there is a perfect, specialized tool for every project. Understanding these categories is the first and most important step to success.