Confused by drilling options? Wrong choice costs time and money. This guide clarifies everything for you.

Many drilling methods exist, like rotary, percussion, and auger. Each is suited for different ground conditions and project goals, offering unique benefits. We'll explore them at Hardrock.

Over my 15 years in the drilling industry here at Hardrock, I've learned that understanding the different ways to drill is crucial. It's not just about making a hole; it's about making the right hole, efficiently and safely. Choosing the wrong method can lead to delays, increased costs, and even project failure. That's why I want to share my insights. We've supplied drilling rigs and tools for all sorts of projects across Africa, the Middle East, and Southeast Asia, so I've seen what works and what doesn't. Let's look at the main drilling methods you'll come across.

What is Rotary Drilling?

Need to drill deep or through hard rock? Old methods too slow? Rotary drilling offers power and speed.

Rotary drilling uses a sharp, rotating drill bit to cut or crush rock. It's very versatile for water wells, oil and gas, and mining exploration, a common method for our clients.

Rotary drilling is a cornerstone of the drilling world. At Hardrock, many of our water well drilling rigs and mining exploration rigs are designed for this. I've seen these machines tackle some tough jobs.

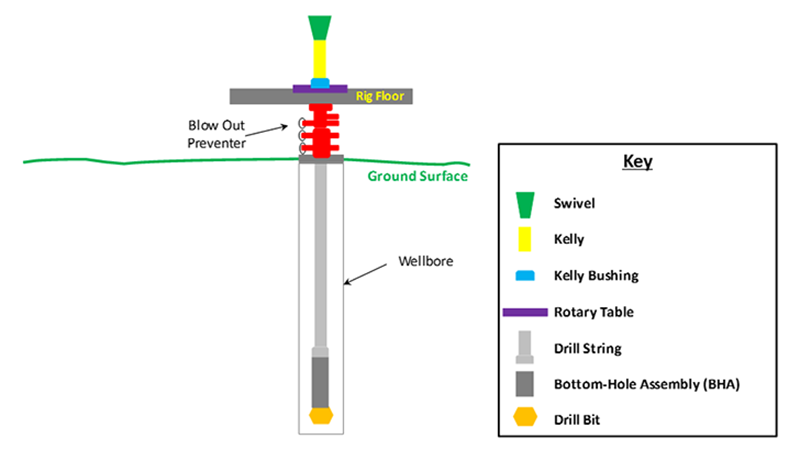

How does it work?

The core idea is simple. A drill string, made of drill rods, has a drill bit at its end. This whole string rotates. The bit, pushed down, grinds or cuts the rock. We use drilling fluid – usually mud (a mix of water and bentonite) or air. This fluid does three things: it cools the bit, it carries the broken rock pieces (cuttings) up to the surface, and it helps stabilize the borehole. For example, when a client like Mohammed in the UAE drills for water in sandy conditions, mud rotary helps keep the hole from collapsing.

What are the good points?

Rotary drilling is generally fast, especially in soft to medium-hard formations. It can reach great depths. You also get good control over the hole. It’s adaptable to a wide range of geological conditions.

What are the not-so-good points?

The equipment can be quite large and needs a significant setup area. If you're using drilling mud, managing and disposing of it can be an issue. In very hard rock, drill bit wear can be high, leading to more frequent replacements and higher costs for toolings.

When should you use it?

It's ideal for water wells, oil and gas exploration, geothermal wells, and deep geotechnical investigations. Many of our clients use our geotechnical drilling rigs with rotary capabilities for soil sampling at depth.

What is Percussion or Hammer Drilling?

Struggling with hard, fractured rock? Rotary bits wearing out too fast? Percussion drilling might be your answer.

Percussion drilling, especially Down-the-Hole (DTH) hammer, breaks rock by repeated hammering. It's excellent for hard rock, used in quarrying, water wells, and foundation piling.

Percussion drilling is an older method, but still very effective, especially DTH. I remember a project in a remote part of Africa where we supplied a DTH rig. The ground was incredibly hard granite, and rotary drilling was too slow. The DTH hammer powered right through it.

How does it work?

Instead of just rotating and pushing, a DTH hammer, located directly behind the drill bit, strikes the bit rapidly. Compressed air powers this hammer and also blows the cuttings up out of the hole. The drill string slowly rotates the bit to ensure the entire bottom of the hole is hit. Think of it like a chisel being hammered and slowly turned. Our Hardrock air compressors are essential for this, providing the high-pressure air needed.

What are the good points?

DTH drilling is very efficient in hard and abrasive rock formations. It produces relatively straight holes. The energy is applied directly at the bit, so there's less energy loss up the drill string. It often requires less down pressure than rotary drilling in hard rock.

What are the not-so-good points?

It can be slower than rotary drilling in softer formations. It's not ideal for unconsolidated or very soft ground, as the hole might collapse. It also typically produces larger cuttings, which can sometimes be harder to clear. Water ingress can also reduce hammer performance.

When should you use it?

Use it for drilling water wells in hard rock, blast holes in quarries and mines, foundation piling, and geothermal boreholes. Our foundation drilling rigs can be equipped with DTH systems for these applications.

What is Auger Drilling?

Need quick, shallow holes in soft ground? Looking for a simple, cost-effective method? Auger drilling is perfect.

Auger drilling uses a helical screw (the auger) to bore into the ground. It's best for soft soils, environmental sampling, and shallow geotechnical investigations.

Auger drilling is one of the simplest methods. I've seen it used many times for soil testing or setting small posts. It's straightforward and gets the job done quickly in the right conditions.

How does it work?

An auger looks like a large corkscrew. It's rotated and pressed into the ground. The soil or soft rock is cut by the auger's blades and carried up to the surface along the helical flights. There are hand-held augers, but for deeper or larger holes, we use machine-powered augers, often mounted on our smaller geotechnical drilling rigs. Continuous flight augers allow for constant drilling and soil removal. Hollow stem augers allow for sampling or installation through the center of the auger.

What are the good points?

It's a relatively fast and inexpensive method for shallow depths in soft, cohesive soils like clay or sand. The equipment is often simpler and more portable than for other methods. It provides a good, relatively undisturbed sample if solid stem augers are used.

What are the not-so-good points?

It's not suitable for hard rock or very loose, caving formations (like dry sand or gravel) unless cased. Depth is generally limited, usually to less than 30-50 meters, though some specialized augers can go deeper. It can be difficult to advance in ground with many cobbles or boulders.

When should you use it?

It's great for environmental soil sampling, geotechnical site investigations, installing monitoring wells, and drilling holes for fence posts or small foundations. Some of our water well drilling customers use augers for the top, softer layers before switching to another method.

What is Core Drilling?

Need to know exactly what's underground? Require an intact sample of rock or soil? Core drilling provides the answers.

Core drilling cuts a cylindrical sample of rock or soil, called a core. It's essential for mineral exploration, geotechnical design, and scientific research to analyze subsurface materials.

Core drilling is all about getting high-quality samples. For mining companies or geotechnical engineers, these cores are invaluable. At Hardrock, we supply specialized core drilling rigs and diamond core bits, which are crucial for this precise work.

How does it work?

A hollow, cylindrical drill bit, often impregnated with diamonds for cutting hard rock, is rotated at the end of a core barrel. As the bit advances, it cuts an annular ring, leaving a central cylinder of rock or soil (the core) that enters the core barrel. Periodically, the core barrel is brought to the surface, and the core sample is retrieved. This process demands careful control of rotation speed and pressure to ensure good core recovery.

What are the good points?

It provides the most representative and relatively undisturbed sample of the subsurface material. This allows for detailed geological logging, structural analysis, and laboratory testing. It can be used in almost any type of formation, from soft soils to very hard rock.

What are the not-so-good points?

Core drilling is generally slower and more expensive than other methods that don't retrieve a solid core. It requires skilled operators to maximize core recovery and quality. The drill bits, especially diamond bits, can be costly.

When should you use it?

It's essential for mineral exploration to identify ore bodies. Geotechnical engineers use it to obtain samples for designing foundations, tunnels, and dams. It's also used in scientific research to study earth's history. Our mining exploration drilling rigs are frequently used for core drilling.

What is Directional Drilling (including HDD)?

Need to drill under a river, road, or building? Or reach an offshore oil reserve? Directional drilling makes it possible.

Directional drilling allows boreholes to be drilled non-vertically. Horizontal Directional Drilling (HDD) is a key type, used for installing utilities and pipelines without trenching.

Directional drilling, especially HDD, is a game-changer. I've seen clients use it to install pipelines under busy highways with minimal disruption. It's a sophisticated technology that requires specialized equipment and expertise.

How does it work?

It starts with a pilot hole drilled along a pre-determined path. Specialized downhole tools, including a steerable drill head and sensors, allow the operator to guide the drill bit. Drilling fluid (mud) lubricates the bit, carries cuttings, and stabilizes the hole. Once the pilot hole reaches the exit point, it's often enlarged by reaming. Then, the product pipe (for utilities, for example) is pulled back through the enlarged hole. It requires precise surveying and steering.

What are the good points?

It allows for drilling beneath obstacles, minimizing surface disruption and environmental impact. It can access reservoirs or targets that are not directly reachable from above. HDD is often faster and less disruptive than open-cut trenching for utility installation.

What are the not-so-good points?

It's a complex and expensive method requiring specialized equipment and highly skilled crews. Accurate geological information is crucial for planning a successful directional drill. There are risks of bore-hole collapse in unfavorable ground or "frac-out" (drilling fluid escaping to the surface).

When should you use it?

For installing utilities (pipelines, cables) under rivers, roads, railways, and sensitive areas. In the oil and gas industry, it's used to access multiple reservoirs from a single platform or to increase wellbore exposure to a formation. Some geothermal projects also use directional drilling. While Hardrock doesn't specialize in HDD rigs, we understand the principles and provide some compatible tooling.

What is Reverse Circulation (RC) Drilling?

Need fast, cost-effective bulk samples in mineral exploration? Concerned about sample contamination? RC drilling is a strong contender.

Reverse Circulation (RC) drilling brings rock cuttings to the surface inside dual-wall drill rods. This provides quick, largely uncontaminated samples, ideal for mineral exploration and grade control.

RC drilling is very popular in the mining industry, especially in regions like Australia and parts of Africa. We've supplied toolings to many RC drilling operations. It's known for its speed and the quality of samples it produces for initial exploration.

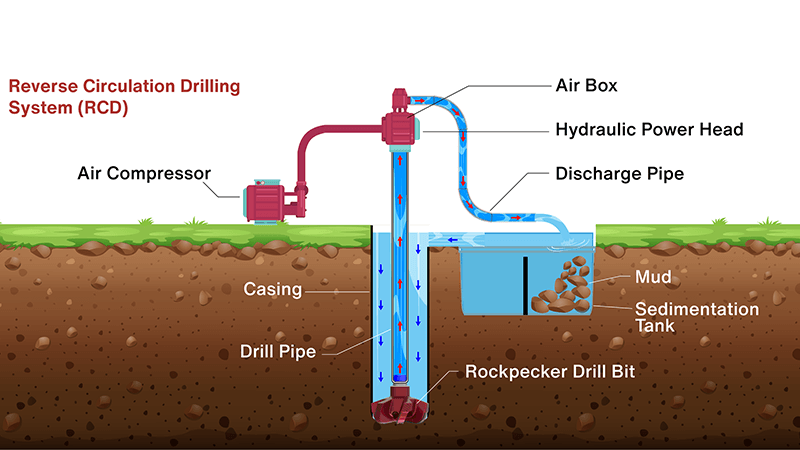

How does it work?

RC drilling uses a pneumatic hammer (similar to DTH) or a tricone bit to break the rock. The key difference is the dual-wall drill pipe. Compressed air is forced down the outer annulus of the pipe. As the air and cuttings are pushed up the inner tube of the drill pipe, they are protected from contamination from the borehole walls. This means the sample arriving at the surface is a direct representation of the rock being cut at the bit face.

What are the good points?

It's much faster and cheaper per meter than core drilling. It provides relatively large, continuous samples that are less prone to contamination than cuttings from conventional rotary drilling. It can operate in a variety of ground conditions, including those with some water.

What are the not-so-good points?

The samples are chips, not solid core, so detailed structural information is lost. It can struggle in very soft, sticky clays or highly fractured, caving ground. Water ingress in large amounts can affect sample quality and recovery. The equipment is specialized.

When should you use it?

It's primarily used in mineral exploration for initial resource definition and grade control. It's also used for in-pit drilling in open-cut mines and sometimes for water bore drilling in specific conditions. Our mining exploration rigs can be adapted for RC, and we supply the necessary RC drill rods and hammers.

What is Sonic Drilling?

Dealing with difficult mixed ground, like boulders and clay? Need high-quality, continuous samples with minimal disturbance? Sonic drilling offers unique capabilities.

Sonic drilling uses high-frequency resonant energy to advance a core barrel or casing. It excels in mixed unconsolidated formations, providing excellent sample recovery and speed.

Sonic drilling is a more advanced and specialized technique. I've been impressed by its performance in very challenging ground conditions where other methods struggle. It's like magic watching it go through mixed layers.

How does it work?

A sonic drill head generates high-frequency (50-150 Hz) vibrations in the drill string. This vibration fluidizes the soil or shears through harder materials directly in front of the bit face, allowing the core barrel or casing to advance rapidly. It can often drill without any drilling fluid, although water or air can sometimes be used to aid cutting removal. The high-frequency action greatly reduces friction on the sides of the drill string.

What are the good points?

It provides exceptional core sample recovery (often 90-100%) in unconsolidated and mixed formations (sands, gravels, clays, boulders). It's very fast in these conditions. It can drill and case a hole simultaneously. It minimizes waste cuttings compared to other methods.

What are the not-so-good points?

Sonic drilling rigs and tooling are expensive. The technology is complex, requiring specialized operators and maintenance. It's less effective in solid bedrock compared to methods like DTH or rotary diamond drilling. The high vibration can be a concern in sensitive areas.

When should you use it?

It's ideal for environmental investigations, geotechnical sampling in complex overburden, mineral sands exploration, and installing monitoring or dewatering wells in difficult ground. It's also used for some geothermal loop installations. While we don't manufacture sonic rigs at Hardrock, we recognize its value for specific, challenging projects.

Conclusion

Many drilling methods exist, each with strengths. Understanding them helps choose the best for your project, ensuring success.