Geotechnical Drilling Rig

Explore Our Products

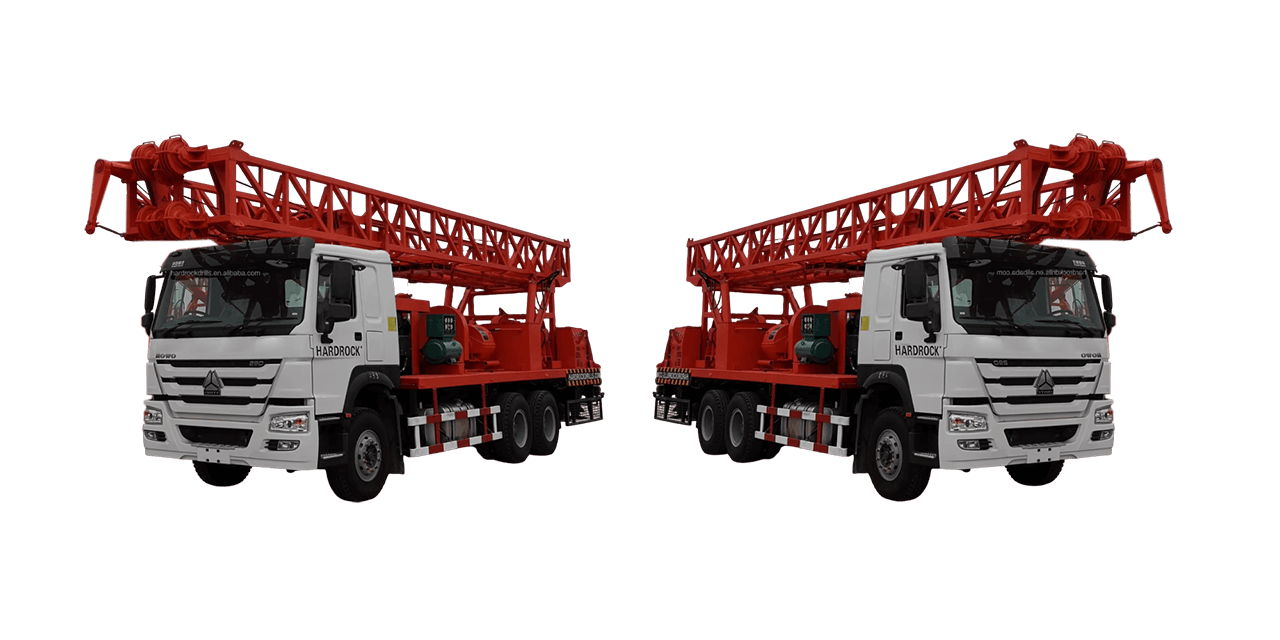

Discover Hardrock’s Geotechnical Drilling Rigs: Tailored for High Precision and Stability in Varied Geological Settings.

Specifications for Selected Models

| Parameters | SPT-H | SPT-C |

|---|---|---|

| Hammer Mass | DPL 10kg, DPM 30kg, DPH 50kg, DPSH & SPT 63.5kg | |

| Number of Blows | 15-30 blows per minute | |

| Dropping Height | 500/750mm adjustable | |

| Window Sampling | 51mm outer diameter, 1m length split sampler (Optional) | Double-layer sampling tube, 51mm outer diameter (57/71/89 can be customized), 10m |

| Size/Weight | 1600x940x1540mm / 230kgs | 820x1500x2400mm (Crawler/Full size) / 845kgs |

| Max Speed | - | 2.5km/hour |

| Rod | Dia. 22mm×1m, 2 pcs; Dia. 32mm×1m, 10 pcs | |

| Brass Cap | One for dia. 22mm rod, one for dia. 32mm rod | |

| Cone | 90° cones, nominal base areas: 10cm², 15cm², 16cm², and 20cm² | |

| Rod Clamp | Suitable for dia. 22mm and 32mm rod and dia. 51mm window sampler | |

| Rod Extraction Unit | Including oil cylinder and clamp (suitable for 20~65mm) | |

| Tools | Included | |

Why Choose Hardrock

Technical Training

Customized Solutions

On-Site Quality Support

24/7 Customer Support

Explore Innovative Drilling Solutions with a Free Consultation from Hardrock

One-Stop Tooling Solutions

Maximize Your Drilling Potential with Hardrock’s Tooling Solutions. Explore our offerings to equip your drilling projects with the right tools for success.

Maximize efficiency with reliable air compression.

Enhance drilling with robust mud circulation.

Precision bit for effective material penetration.

Dependable rod for deep and precise drilling.

Discover Our Successful Project

Water Well Project in Tanzania

- Location: Mwanza Region, Tanzania

- Project: Rural water supply

- Challenge: Deep aquifer access in hard rock formation, limited infrastructure

Geothermal Exploration in PHL

- Location: Mindanao Island

- Geothermal power exploration

- Challenge: High-temperature formations, complex geology

Mining Exploration in Chile

- Location: Atacama Region

- Project: Copper deposit exploration

- Challenge: High-altitude operation (3,500m), extreme weather

Foundation Construction in UAE

- Location: Dubai

- Project: High-rise building foundation

- Challenge: Dense urban area, strict noise regulations

Oil Exploration in Kazakhstan

- Location: Mangystau Region

- Project: Oil exploration program

- Challenge: Remote location, harsh winter conditions

Knowledge of Geotechnical Drilling Rig

What Is a Geotechnical Drilling Rig and How Does It Work?

Basic Operation:

- Rig setup at site

- Drill through soil/rock layers

- Collect core samples

- Perform in-situ tests

Types of Geotechnical Drilling Rigs?

Based on drilling methods:

- Rotary Geotechnical Drilling Rigs

- Percussion Geotechnical Drilling Rigs

Based on mobility:

- Track-mounted Geotechnical Drilling Rigs

- Truck-mounted Geotechnical Drilling Rigs

- Trailer-mounted Geotechnical Drilling Rigs

Key Factors to Consider When Choosing a Geotechnical Drilling Rig?

Match depth capacity and sampling needs to project specifications.

Soil types and rock formations determine required drilling power.

Space constraints and terrain influence rig size choice.

Choose between hydraulic or mechanical based on efficiency needs.

Balance investment costs against expected project returns.

Customer Visits Factory

A glimpse into the experience of our valued customers as they visit our factory to witness the quality and precision behind our products.

Testimonials from Satisfied Customers

Geotechnical Drilling Rig Resources

Let’s Build Your Drilling Success Together!

Whether you’re looking for a customized drilling solution, technical advice, or simply want to learn more about our services, our team is ready to assist.