Confused about drilling rigs? They're complex machines that can seem overwhelming at first. Let's break it down.

A drilling rig is specialized equipment used to drill holes in the earth's surface for water wells, mineral exploration, oil and gas extraction, geothermal energy, or construction purposes.

As someone who has manufactured drilling rigs for years at Hardrock, I can tell you that these machines are engineering marvels. Think of a drilling rig as a powerful workshop on wheels or tracks. It's like a giant power drill, but much more complex and capable. The main purpose is to create holes in the ground, but how it does this varies by application. For example, the water well drilling rigs we sell to clients like Mohammed Al-Rahman in Dubai are designed differently from our mining exploration rigs. Water well rigs focus on creating large-diameter holes in relatively soft formations, while mining rigs need to drill smaller, precise holes in hard rock. Each rig is a combination of mechanical, hydraulic, and electrical systems working together. The size can range from small portable units mounted on trailers to massive structures used for deep oil wells. Understanding what a drilling rig is means understanding its purpose, capabilities, and limitations.

How Does a Drilling Rig Works?

Wonder how these machines penetrate the earth? The process combines power, rotation, and circulation in a coordinated dance.

Drilling rigs work by combining three main actions: applying downward force on a drill bit, rotating the drill string, and circulating drilling fluid to remove cuttings and cool the bit.

The operation of a drilling rig is fascinating. At Hardrock, we design our rigs to perform this complex process efficiently. Here's how it works:

- Power Generation

- Engine provides power to all systems

- Hydraulic systems distribute power where needed

- Electric systems control operations

- Drilling Action

- Downward force (pull-down) pushes the bit into the ground

- Rotation system turns the drill string

- Drill bit breaks up the formation

- Material Removal

- Drilling fluid1 (mud or air) is pumped down

- Cuttings are carried to the surface

- Continuous circulation maintains hole stability

The process requires careful coordination of all these systems. When Mohammed Al-Rahman's team operates our rigs in UAE's harsh desert conditions, they rely on this synchronized operation to maintain efficient drilling. The operator must constantly monitor and adjust these systems based on the formation being drilled and other conditions.

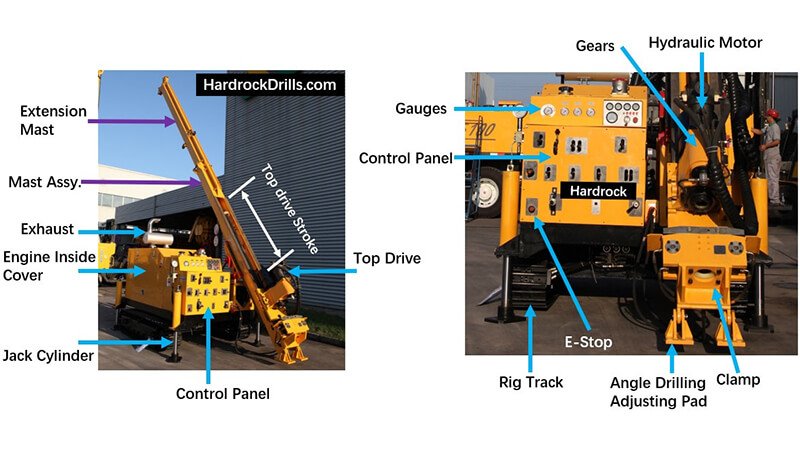

What Are the Key Components of a Drilling Rig?

Missing key components in your knowledge? Understanding each part's role is crucial for successful operation.

Key components include the power unit, mast, rotary head, feed system, control panel, mud pump2 or air compressor, and various auxiliary systems necessary for drilling operations.

From my experience manufacturing drilling rigs at Hardrock, I've learned that each component plays a vital role. Let me break down the main parts:

| Component | Function | Importance |

|---|---|---|

| Power Unit | Provides energy to all systems | Heart of the machine |

| Mast | Supports drilling components | Structural backbone |

| Rotary Head | Creates drilling rotation | Main working component |

| Feed System | Controls bit pressure | Critical for drilling efficiency |

| Control Panel | Operation interface | Brain of the operation |

| Circulation System | Removes cuttings, cools bit | Essential for continuous drilling |

| Auxiliary Systems | Support main operations | Enhances performance |

These components must work together seamlessly. For instance, when our client Mohammed Al-Rahman drills water wells in Dubai, the power unit must be robust enough to handle the heat, while the circulation system needs to manage desert sand effectively. Understanding these components helps operators maintain efficiency and troubleshoot problems quickly.

What Are the Main Types of Drilling Rigs?

Different projects need different rigs. Choosing the wrong type wastes time and money. Know your options.

Main types include water well rigs, geotechnical rigs3, foundation drilling rigs4, mining exploration rigs, and oil/gas rigs, each designed for specific applications.

At Hardrock, we manufacture several types of drilling rigs, each designed for specific purposes. Here's a comprehensive breakdown:

- Water Well Drilling Rigs

- Purpose: Fresh water access

- Features: Large diameter capability

- Methods: Rotary, DTH hammer

- Common in: Rural development, agriculture

- Geotechnical Drilling Rigs

- Purpose: Soil investigation

- Features: Sample collection ability

- Methods: Core drilling, SPT

- Common in: Construction projects

- Foundation Drilling Rigs

- Purpose: Building support

- Features: High torque systems

- Methods: Large diameter drilling

- Common in: Construction sites

- Mining Exploration Rigs

- Purpose: Mineral discovery

- Features: Core sampling ability

- Methods: Diamond drilling

- Common in: Mining operations

Each type has specific advantages. For example, Mohammed Al-Rahman's company uses both water well and foundation rigs because they handle different project requirements in UAE's construction sector.

Where Are Drilling Rigs Commonly Used?

Wondering about drilling applications? These machines work across various industries and environments.

Drilling rigs are used in construction sites, water resource development, mining operations, oil fields, and geotechnical investigations5 worldwide.

Through our global operations at Hardrock, I've seen drilling rigs at work in diverse settings. Here's where you'll commonly find them:

- Construction Industry

- Building foundations

- Bridge supports

- Underground parking structures

- Soil investigation

- Water Resources

- Municipal water supplies

- Agricultural irrigation

- Private water wells

- Groundwater monitoring

- Mining Sector

- Mineral exploration

- Resource evaluation

- Blast hole drilling

- Ventilation shafts

- Energy Development

- Oil and gas exploration

- Geothermal wells

- Coal bed methane

- Underground storage

- Environmental Projects

- Contamination studies

- Monitoring wells

- Soil sampling

- Remediation projects

Each application requires specific expertise and equipment. For instance, our client Mohammed Al-Rahman focuses on water well and foundation projects in Dubai's expanding construction sector.

What Maintenance Do Drilling Rigs Require?

Neglecting maintenance? That's a costly mistake. Regular care keeps your rig running efficiently.

Drilling rigs require daily inspections, regular fluid checks, component lubrication, wear part replacement, and scheduled comprehensive maintenance to ensure reliable operation.

Based on our experience at Hardrock, proper maintenance is crucial for rig longevity. Here's a comprehensive maintenance approach:

- Daily Maintenance

- Check fluid levels

- Inspect wear parts

- Clean key components

- Monitor gauges

- Document operations

- Weekly Tasks

- Grease all points

- Check belt tensions

- Inspect hydraulic hoses

- Test safety systems

- Clean thoroughly

- Monthly Requirements

- Change filters

- Check alignment

- Inspect structural elements

- Test backup systems

- Update maintenance logs

- Annual Service

- Major component inspection

- Hydraulic oil change

- Structural certification

- Safety system overhaul

- Complete documentation

Following these schedules prevents breakdowns. Mohammed Al-Rahman's success in Dubai's harsh conditions comes partly from strict maintenance routines we helped establish.

Conclusion

Understanding drilling rigs is essential for success in drilling operations. From basic components to maintenance, this knowledge helps you choose and operate the right rig for your needs.

-

Discover the critical role of drilling fluid in maintaining efficiency and safety during drilling operations by visiting this resource. ↩

-

Exploring the mud pump's operation will enhance your knowledge of its critical role in maintaining drilling efficiency and safety. ↩

-

Learn about geotechnical rigs and how they play a crucial role in site investigations and construction projects. ↩

-

Discover the significance of foundation drilling rigs in ensuring stable and secure building foundations. ↩

-

Learn about the importance of geotechnical investigations in ensuring safe and effective construction practices. ↩