Struggling to choose between DTH and Top Hammer drilling? Picking the wrong one wastes time and money. This guide clarifies the key differences to help you choose wisely.

DTH drilling excels in deep, large-diameter holes in hard rock, with the hammer at the bottom. Top hammer is faster and more economical for shallow, smaller holes but loses power with depth. Your choice depends on hole depth, diameter, and rock conditions.

Many of my clients ask me which method is "better." The truth is, they are not competitors. They are specialized tools for different jobs. I've sold both types of rigs from my company, Hardrock, to contractors all over the world, from Africa to the Middle East. Understanding how they work and where they shine is the most important step in selecting the right equipment. Let's dig into the details so you can make the best decision for your next project.

How Do DTH and Top Hammer Drilling Actually Work?

The terms DTH and Top Hammer sound technical and confusing. Not understanding the fundamental difference can lead you to buy a rig that is completely wrong for your geological conditions.

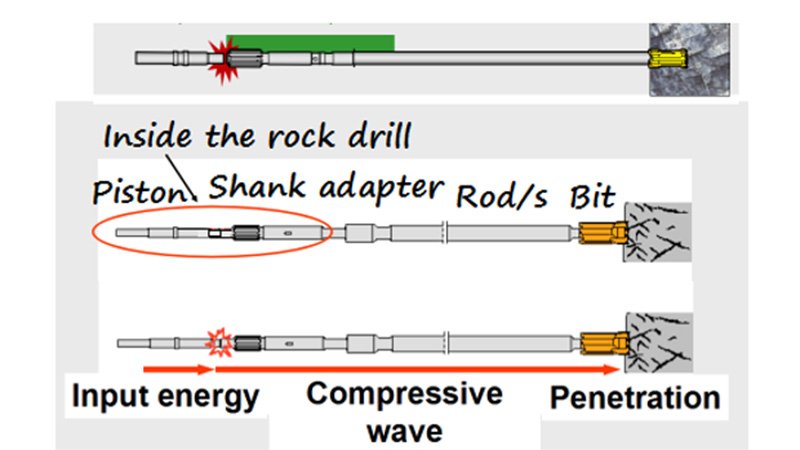

DTH (Down-The-Hole) drilling puts the hammer directly at the bottom of the hole, hitting the bit. Top Hammer drilling keeps the hammer on the rig, sending impact energy down through the drill rods to the bit.

I always explain it to my customers with a simple analogy. Imagine you need to hammer a nail. DTH drilling is like hitting the nail directly with the hammer. All the energy goes right into the nail. Top Hammer drilling is like placing a long metal rod on the nail and hitting the top of the rod with your hammer. The energy has to travel all the way down the rod to reach the nail.

- DTH (Down-The-Hole) Drilling: The percussive hammer is a piston that follows the drill bit down into the borehole. Compressed air is forced down the drill rods to power this piston, which strikes the bit at high speed. The energy transfer is extremely efficient because the impact happens right at the rock face. The exhaust air then blows the rock cuttings up and out of the hole.

- Top Hammer Drilling: The hammer, usually hydraulic, is mounted on the rig at the surface. It strikes the top of the drill rod string with very high frequency. This impact energy travels down the series of connected rods as a shockwave, eventually reaching the bit at the bottom. This method is very fast in the right conditions.

The key takeaway is where the impact happens. DTH is at the bottom; Top Hammer is at the top. This single difference is responsible for all the other performance variations between them.

What Are the Main Differences Between DTH and Top Hammer?

You know the basic principles, but how do they translate to performance on the job site? Picking the wrong rig leads to slow progress, broken tools, and higher operational costs.

The key differences are in energy transfer, depth and diameter capability, and cost. DTH maintains power at any depth for large holes, while Top Hammer is faster for shallow, small holes but loses power and accuracy as it goes deeper.

Let's break down the practical differences I discuss with clients like Mohammed when he's planning a new project in Dubai.

1. Energy Transfer and Efficiency

This is the core of it all. With DTH, the hammer is always right behind the bit, so the impact energy is consistent, no matter if you're drilling 20 meters or 200 meters deep. With Top Hammer, the energy has to travel through the entire drill string. The longer the string, the more energy is lost along the way.

| Aspect | DTH Drilling | Top Hammer Drilling |

|---|---|---|

| Impact Location | Directly at the bottom of the hole | At the top, sent down the drill rods |

| Energy Loss | Very low, almost zero | Increases significantly with depth |

| Drilling Stability | High, consistent performance | Decreases in deeper holes |

2. Drilling Depth and Hole Diameter

Because of the energy loss issue, Top Hammer is best for shallow drilling, typically less than 30 meters. It excels at small-to-medium diameter holes (25-127 mm). DTH, on the other hand, is the champion of depth and diameter. It can drill hundreds of meters deep and create large holes (76-450 mm or more) without losing performance.

3. Drilling Speed and Quality

In a race to drill a shallow, 50mm hole, the Top Hammer rig will almost always win because its impact frequency is much higher (40-60 Hz vs. DTH's 10-20 Hz). However, in a deep, 150mm hole in hard granite, the DTH rig's powerful, efficient blows will be much faster overall. DTH also produces straighter, higher-quality holes because the stiff, large-diameter hammer acts as a guide in the hole. Top Hammer holes can deviate more as the long, thin drill string can bend.

4. Cost and Consumables

Top Hammer rigs generally have a lower initial purchase price. However, the operational costs can be higher because the drill rods must endure the constant impact, leading to faster wear and tear. DTH rigs and their large compressors have a higher initial cost, but the drill rods last much longer since they only have to handle rotation and air pressure, not the impact stress.

When Should You Use DTH vs. Top Hammer Drilling?

You know the theory, but which rig do you actually send to a job site? Using the wrong tool is a disaster waiting to happen, resulting in schedule delays and financial losses.

Use DTH for deep holes, large diameters, and hard rock, like in mining or water well drilling. Use Top Hammer for high-volume, shallow, small-diameter holes, like in tunneling, quarrying, and construction site work.

The choice becomes very clear when you look at the typical applications for each. I've equipped contractors for all of these scenarios.

DTH Drilling Applications

Choose DTH when your project involves depth, large diameters, or hard rock.

- Deep Water Wells & Geothermal Wells: When a client needs to drill a 200-meter water well through hard rock in Africa, DTH is the only conversation we have. It's the only way to maintain drilling progress at that depth.

- Open-Pit Mine Blasting: For drilling deep production blast holes (over 20 meters), DTH is standard.

- Foundation and Piling Work: For large-diameter holes needed for building foundations or bridges.

- Slope Stabilization: When drilling deep holes for rock anchors.

Top Hammer Drilling Applications

Choose Top Hammer when you need speed for many shallow holes.

- Tunneling and Drifting: Perfect for drilling the pattern of small blast holes or rock bolt holes in underground mining and civil engineering. The smaller size of the rigs is also an advantage in tight spaces.

- Quarrying and Construction: For drilling shallow blast holes on benches or for general construction site rock-breaking. The high speed makes it very productive.

- Geotechnical Surveying: When many shallow sample holes are needed quickly.

Here is a simple guide to help you choose:

| If your priority is... | Then choose... |

|---|---|

| Deep holes (>30m), large diameters (>127mm), hard rock | DTH Drilling |

| Shallow holes (<30m), small diameters, high speed | Top Hammer Drilling |

| Hole straightness and precision | DTH Drilling |

| Lower initial budget, high volume of shallow holes | Top Hammer Drilling |

Conclusion

DTH and Top Hammer are not rivals but specialized tools. DTH is for depth, power, and precision in hard rock, while Top Hammer offers speed and economy for shallow holes.