Choosing the right drilling rig can feel overwhelming. A wrong choice costs time and money. This guide simplifies the different rig types to help you make the best decision for your project.

Well drilling rigs are categorized by their application (water, oil, geothermal), mobility (fixed, mobile, portable), power source (mechanical, hydraulic, electric), and functional capability (rotary, directional, core sampling). Understanding these types ensures you select the optimal machine for your specific geological conditions and project goals.

The world of drilling is vast, and not every rig is created equal. I've spent years helping clients like you navigate these choices. From drilling a simple water well in a remote village to complex geothermal projects, the right rig is the key to success. Let's break down the main types so you can see which one fits your needs.

How Are Rigs Classified by Their Application?

Do you need water, oil, or minerals? The purpose of your well is the first and most important factor. Using a rig designed for water to drill for oil is a recipe for failure.

Drilling rigs are primarily classified by their intended application: water well drilling for accessing groundwater, oil and gas drilling for hydrocarbon extraction, and specialized rigs for geothermal energy, mining exploration, and scientific research. Each category has unique design features to handle specific depths and formations.

The target resource completely changes the machine's design. A water well rig might only need to go a few hundred meters, while an oil rig must go thousands. At Hardrock, we match the rig's power, depth capacity, and drilling method to the specific application.

Water Well Drilling Rigs

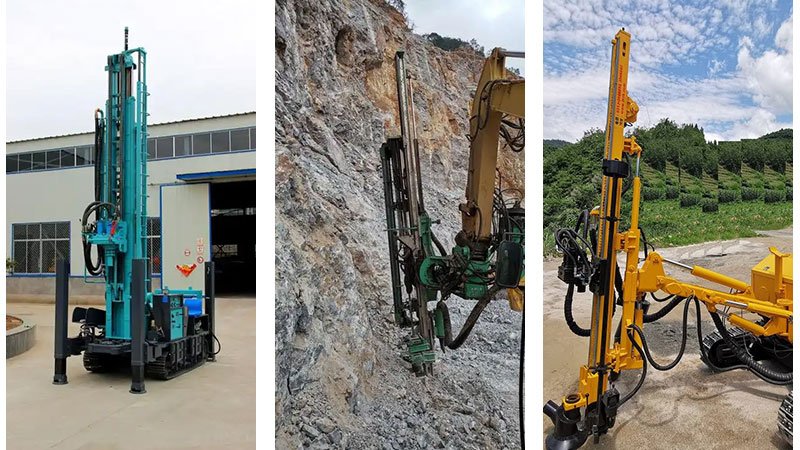

These are some of the most common rigs. They range from small, portable units for shallow wells in rural areas to powerful rotary or DTH (Down-The-Hole) rigs for deep aquifers. For a client in Southeast Asia needing agricultural wells, we provided a trailer-mounted rig that could easily move between farm plots.

Oil & Gas Drilling Rigs

These are the giants of the industry. Onshore, you have conventional land rigs, including some designed for swamps or deserts. Offshore, you find massive structures like jack-up rigs, semi-submersibles, and drillships. There are also smaller workover rigs used to service existing wells.

Geothermal, Mining & Exploration Rigs

This category is highly specialized. Geothermal rigs must handle high temperatures. Core drilling rigs are designed to extract perfect rock samples for mineral analysis. Blast-hole rigs are used in quarries to prepare rock for excavation.

What Are the Different Rig Types Based on Mobility?

Will your rig stay in one place for months, or does it need to move every few days? Your project's logistics will determine the best installation format. A wrong choice here creates massive operational headaches.

Based on mobility, drilling rigs are classified as fixed/stationary for long-term projects, mobile/transportable (truck, trailer, or crawler-mounted) for versatility and moving between sites, and compact/portable for accessing remote or restricted locations.

I once had a client, Mohammed from Dubai, who needed to drill multiple foundation holes across a large construction site with uneven ground. A truck-mounted rig would have struggled, but a crawler-mounted rig moved across the rough terrain with ease.

Fixed / Stationary Rigs

These rigs are designed for deep, long-duration projects, like a major oil field. They are often skid-mounted and assembled on-site. Once in place, they don't move until the project is completely finished. Their stability allows them to drill to incredible depths.

Mobile / Transportable Rigs

This is the most common category for water well, geotechnical, and smaller exploration projects.

- Truck-mounted rigs are great for sites with road access.

- Trailer-mounted rigs can be towed by a separate vehicle.

- Crawler-mounted rigs use tracks, like a tank, to navigate very rough or soft ground where wheels would get stuck.

Compact & Mini / Portable Rigs

When access is extremely limited, you need a portable rig. These can be broken down into smaller components and carried by hand or a small vehicle. They are perfect for geotechnical testing inside buildings or for drilling in dense forests or mountainous regions.

How Does the Power Source Define a Drilling Rig?

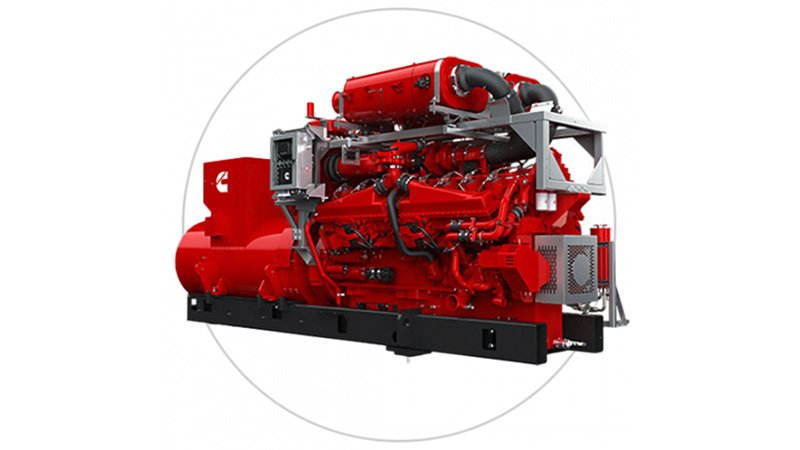

Are you working near a power grid or in the middle of nowhere? The rig's power system is its heart. The choice affects performance, maintenance, and environmental impact.

Drilling rigs are defined by their power mechanism: mechanical rigs use diesel engines and gear systems, hydraulic rigs use fluid pressure for precise control, and modern electric or hybrid rigs offer lower emissions and operational costs where a power source is available.

The power source is a huge factor in the Total Cost of Ownership (TCO). A diesel rig might have a lower upfront cost, but fuel and maintenance can be expensive. An electric rig is more efficient, but you need a reliable power grid or a large generator. We help clients analyze these trade-offs.

Mechanical / Diesel-Powered Rigs

These are the traditional workhorses. A powerful diesel engine drives the rig through a system of clutches and gears. They are robust and can work anywhere you can get fuel. However, they are noisy, require significant maintenance, and have higher emissions.

Hydraulic-Driven Rigs

Most modern rigs use hydraulics. An engine (diesel or electric) powers a pump that pressurizes fluid. This fluid then drives motors that control rotation, feed pressure, and other functions. Hydraulics offer smoother operation, precise control, and better safety features.

Electric / Hybrid Rigs

As the world moves toward sustainability, electric rigs are becoming more popular. They are quieter, more efficient, and produce zero on-site emissions if connected to the grid. Hybrid rigs combine a smaller diesel engine with a battery system to improve fuel efficiency and reduce emissions.

What Special Functions Can Drilling Rigs Have?

Do you just need a straight hole, or something more complex? Some projects require advanced capabilities. Knowing these special functions can open up new possibilities for your work.

Beyond standard vertical drilling, rigs can have special functions like directional drilling to reach targets horizontally, core sampling to extract geological samples for analysis, and percussion or cable-tool methods for specific rock formations where rotary drilling is less effective.

We worked with a mining company in Africa that needed to understand the exact size and shape of an ore body. A standard rig wouldn't work. We supplied them with a core drilling rig that could extract continuous rock samples, giving their geologists a perfect picture of what was underground.

| Drilling Function | Primary Use | Key Feature |

|---|---|---|

| Rotary Drilling | General purpose (water, oil, construction) | A rotating drill bit grinds away the rock. |

| Directional Drilling | Oil/gas, utility installation | Can steer the drill bit to drill horizontally. |

| Core & Sampling | Mining exploration, geotechnical | A hollow bit extracts a solid cylinder of rock. |

| Percussion / Cable Tool | Unconsolidated ground, shallow water wells | A heavy bit is repeatedly lifted and dropped. |

Directional drilling is amazing technology. It's used to install utility lines under rivers or highways without digging a trench. In the oil and gas industry, a single offshore platform can use directional drilling to reach multiple targets in a reservoir from one location, saving enormous amounts of money.

How Do You Choose the Right Drilling Rig for Your Project?

You've seen the options, but how do you make the final decision? A systematic approach is key. Choosing the right rig is a balance of technical needs and financial realities.

To select the optimal rig, you must analyze your project's key criteria (depth, geology), mobility requirements, and power availability. Then, consider the Total Cost of Ownership (TCO), including initial purchase, operating costs, and maintenance, not just the sticker price.

This is where my team and I spend most of our time with clients. It's about more than just selling a machine; it's about providing a solution. We act as consultants to ensure the rig you buy will be profitable for you for years to come.

Key Selection Criteria

First, we look at the technical needs.

- Depth and Geology: How deep do you need to go? What kind of rock or soil will you be drilling through? This determines the rig's power and drilling method.

- Mobility and Site Access: How will you get the rig to the site? Is the terrain rough? This points you toward a truck, crawler, or portable model.

- Power and Environment: Is electricity available? Are there strict emissions regulations? This helps decide between diesel, hydraulic, and electric systems.

Cost-Benefit & Total Cost of Ownership (TCO)

Don't just look at the initial price tag. A cheaper rig might cost you more in the long run. Consider fuel consumption, the cost and availability of spare parts, and maintenance requirements. A reliable rig with good support, like we provide at Hardrock, has a much lower TCO.

Conclusion

Choosing the right drilling rig is vital for your project's success. By understanding the types based on application, mobility, power, and function, you can make an informed decision.