Struggling to choose a water well rig? The wrong choice wastes money and time. Find clarity with these key selection points.

Selecting the right water well drilling rig involves evaluating price, operation costs, drilling efficiency, method, after-sales service, spare parts, safety features, and environmental standards for optimal long-term performance.

Making the right choice for a water well drilling rig can feel overwhelming. There are so many factors to consider, and a mistake can be costly. As I always tell my clients at Hardrock, like Mohammed Al-Rahman from Dubai, it's not just about the initial purchase. It's about finding a machine that will serve you reliably and efficiently for years to come. My insight is that choosing the right water well drilling rig isn’t just about cost—it’s about efficiency, safety, and long-term reliability. Every detail matters in making the right decision. Let's break down the essential points to guide your decision.

How Does Price Influence the Selection of a Water Well Drilling Rig?

Budget tight for a new rig? Price is a big factor, but the cheapest isn't always best. Understand true value.

Price is a primary filter, but it should be weighed against quality, features, and long-term value. A higher initial investment can often mean lower operational costs and greater durability over time.

When I discuss price with potential customers, I always stress looking beyond the sticker. The initial purchase price is just one part of the equation.

- Initial Investment vs. Total Cost of Ownership (TCO): A cheaper rig might save money upfront. But if it breaks down often or consumes excessive fuel, its TCO will be higher. At Hardrock, we focus on top quality materials and engineering, which might mean a slightly higher initial cost but better long-term value.

- Quality of Components: The quality of the engine, hydraulic system, and drilling components directly impacts reliability and lifespan. Investing in a rig with reputable components pays off.

- Brand Reputation and Resale Value: A rig from a well-regarded manufacturer often holds its value better. This is important if you plan to upgrade or sell in the future.

- Customization Costs: Standard rigs might not fit every need. Consider if customization is required and factor that into the price. We offer customized solutions to meet specific drilling conditions.

Thinking about price this way helps make a more informed decision.

Why Should Operation Cost Be Considered Before Buying a Drilling Rig?

Rig bought, but fuel bills sky-high? Hidden operation costs can cripple profits. Factor them in upfront for financial health.

Operation costs, including fuel, maintenance, labor, and consumables, significantly impact a rig's lifetime profitability. Evaluating these upfront prevents unexpected financial burdens and ensures sustainable operations.

Operation cost is a major concern for pragmatic business owners like Mohammed Al-Rahman. It's the money you spend every day to keep the rig running.

- Fuel Consumption: This is a big one. A fuel-efficient engine can save thousands over the rig's lifetime. We ensure our Hardrock rigs are optimized for reasonable fuel usage.

- Maintenance Requirements: How often does the rig need servicing? Are parts easy to get and affordable? Frequent or expensive maintenance eats into profits.

- Labor Costs: How many people does it take to operate the rig safely and efficiently? Some modern rigs offer automation that can reduce labor needs.

- Consumables: Think about drill bits, drill rods, and drilling fluids. The wear rate and cost of these items add up. We supply high-quality toolings designed to last.

- Training Needs: If a rig is complex, you might need to invest more in operator training, which is an initial operational cost.

Considering these factors ensures the rig you choose supports a profitable operation.

How Can Drilling Efficiency Affect Overall Project Performance?

Slow drilling losing you contracts? Efficiency is more than speed; it's about overall productivity. Boost your project success rates.

Drilling efficiency, measured by penetration rate, setup time, and reliability, directly impacts project timelines, costs, and client satisfaction. Faster, more reliable rigs complete more jobs profitably.

Drilling efficiency is where the rubber meets the road, or rather, the bit meets the rock. It directly impacts how many wells you can drill and how profitable each job is.

- Penetration Rate (ROP): How fast can the rig drill through different formations? A higher ROP means quicker job completion. Our rigs are designed for optimal ROP.

- Setup and Teardown Time: How long does it take to get the rig ready to drill and then pack it up? Less time spent on setup means more time drilling.

- Automation Features: Features like automated rod handling can speed up operations and reduce manual labor, increasing overall efficiency.

- Rig Reliability and Uptime: A rig that's constantly breaking down is inefficient, no matter how fast it drills when it's working. Quality construction is key here.

- Match to Geological Conditions: An efficient rig is one that's well-suited to the specific geology you'll be drilling in. This links back to choosing the right drilling method.

Higher efficiency means happier clients and a healthier bottom line.

What Impact Does the Chosen Drilling Method Have on Rig Selection?

Wrong rig for the ground type? Matching the drilling method to geology is crucial. Select the right tool for success.

The drilling method (e.g., mud rotary, air rotary, DTH) dictates rig specifications like power, torque, and flushing capacity. Choosing a rig compatible with the intended method and geology is essential.

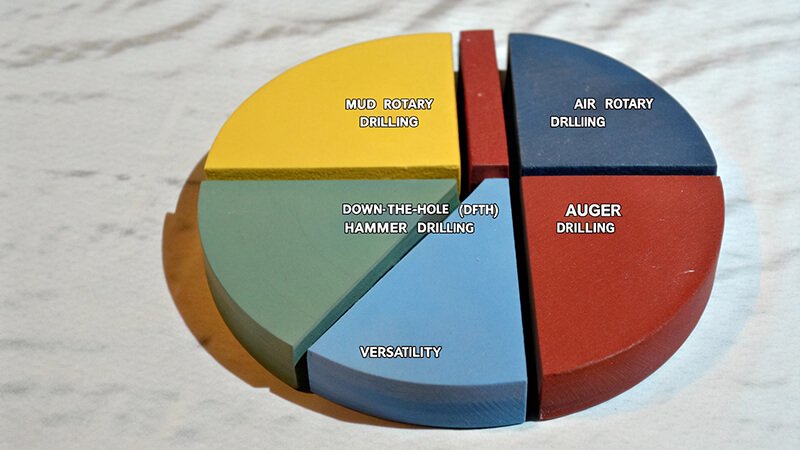

The ground beneath our feet varies hugely, and so do the methods to drill through it. Your chosen drilling method fundamentally shapes the type of rig you need.

- Mud Rotary Drilling: Common for softer to medium formations. Requires a rig with a good mud pump system for circulation. Many of our Hardrock water well rigs excel here.

- Air Rotary Drilling: Better for consolidated formations. Needs a powerful air compressor. The rig must be able to handle the forces involved.

- Down-the-Hole (DTH) Hammer Drilling: Ideal for hard rock. The rig needs to provide rotation and high-pressure air for the hammer. This is a specialty for us.

- Auger Drilling: Suitable for shallow wells in soft, unconsolidated materials. Requires specific torque and auger handling capabilities.

- Versatility: Some rigs are designed to handle multiple methods. If you expect varied geological conditions, a versatile rig, perhaps with customization, could be a good investment.

Matching the rig to the method ensures you can tackle the job effectively.

Why Is After-Sales Service Critical for Long-Term Equipment Reliability?

Rig down, no support in sight? Good after-sales service is your lifeline. Don't overlook this vital aspect for peace of mind.

Reliable after-sales service, including technical support, training, and warranty, ensures minimal downtime and extends the rig's operational life, making it critical for long-term reliability and ROI.

For clients like Mohammed, who prioritizes reliability, after-sales service is non-negotiable. A drilling rig is a complex piece of machinery, and things can go wrong.

- Technical Support Availability: When you have a problem, can you get expert help quickly? This includes response time, expertise, and clear communication. We strive to overcome language barriers for international clients.

- Training Programs: Proper training for operators and maintenance staff can prevent many issues and ensure the rig is used efficiently and safely. We offer this at Hardrock.

- Warranty Terms and Coverage: A good warranty provides peace of mind and covers unexpected manufacturing defects. Understand what's covered and for how long.

- On-site Support Capability: For major issues, can the supplier send a technician? This is especially important for equipment operating in remote areas or internationally.

- Remote Diagnostics: Some modern rigs can be diagnosed remotely, speeding up troubleshooting.

Strong after-sales service from a supplier like Hardrock turns a purchase into a long-term partnership.

How Important Is Spare Parts Availability for Maintenance and Downtime?

Need a part, but it's weeks away? Spare parts access keeps your rig running. Prioritize this for continuous uptime.

Readily available and affordable spare parts are crucial for minimizing downtime during maintenance or repairs. Delays in sourcing parts can halt operations and lead to significant financial losses.

Mohammed Al-Rahman has mentioned long lead times for spare parts as a major pain point. This is a common concern in the drilling industry.

- Manufacturer's Parts Stock: Does the manufacturer, like us at Hardrock, keep a good inventory of common wear parts and critical components? Our 8000 sqm factory helps with this.

- Local Dealer Network/Distribution: If you're buying internationally, does the supplier have a way to get parts to you efficiently in your region?

- Lead Times for Parts Delivery: How long does it actually take for parts to arrive once ordered? This can vary greatly.

- Cost of Common Wear Parts: Frequent replacement parts shouldn't break the bank.

- Risk of Counterfeit Parts: Sourcing from unreliable channels can lead to using counterfeit parts, which can damage your rig or perform poorly. Always aim for genuine parts.

Ensuring good spare parts availability is key to keeping your rig—and your business—drilling.

What Safety Features Should You Look for in a Drilling Rig?

Worried about on-site accidents? Safety features protect your crew and investment. Make safety a non-negotiable top priority.

Essential safety features include emergency stops, guardrails, proper lighting, automated rod handling, and stable outriggers. These protect operators and comply with safety regulations, minimizing accident risks.

Safety on a drill site is paramount. A good rig is a safe rig, protecting your most valuable asset: your people.

- Emergency Stop Systems: Easily accessible e-stops are crucial to quickly halt operations in an emergency.

- Guarding for Moving Parts: All rotating shafts, chains, and belts should be properly guarded to prevent entanglement.

- Operator Cabin Design: If the rig has a cabin, it should offer good visibility, ergonomic controls, and protection from the elements and potential hazards.

- Automated Pipe/Rod Handling: This significantly reduces the manual labor involved in tripping rods, which is a common source of injuries. We are incorporating more automation in our Hardrock designs.

- Stability Systems: Robust outriggers and leveling systems are vital to ensure the rig is stable during operation, especially on uneven ground.

- Adequate Lighting: For night operations or low-light conditions, good lighting is essential for safe work.

Investing in a rig with comprehensive safety features is an investment in your crew's well-being and your company's reputation.

How Can Environmental Protection Standards Shape Your Rig Choice?

Facing strict environmental rules? Your rig choice must comply. Drill responsibly and avoid costly penalties or project delays.

Modern drilling rigs should meet environmental standards regarding noise levels, emissions, and fluid containment. Choosing a compliant rig avoids fines, ensures access to sensitive projects, and promotes sustainable operations.

Environmental regulations are becoming stricter worldwide. Choosing a rig that meets these standards is not just good practice; it's often a necessity.

- Engine Emission Standards: Engines must comply with local emission regulations (e.g., EPA Tiers in North America, Euro Stages in Europe). This impacts air quality.

- Noise Reduction Features: Drilling can be noisy. Rigs with noise dampening features are preferred, especially when working near residential areas.

- Spill Prevention and Containment Systems: Hydraulic fluids and fuel can contaminate soil and water. Systems to prevent and contain spills are important.

- Dust Suppression Systems: Especially in air drilling, dust can be a major issue. Effective dust suppression protects worker health and the environment.

- Use of Biodegradable Hydraulic Fluids: Some projects may require or encourage the use of environmentally friendly fluids.

At Hardrock, we are increasingly aware of these requirements and work to ensure our rigs can meet diverse global standards, supporting our clients in drilling responsibly.

Conclusion

Selecting the right water well rig involves balancing cost, efficiency, support, safety, and environmental impact. Careful consideration of these 8 key points leads to long-term operational success.