Rotary drilling rigs have revolutionized the way we access underground resources, playing a vital role in the exploration and extraction of oil, gas, and geothermal energy. By using a rotating drill bit to cut through subsurface formations, these rigs have become the industry standard for deep well drilling around the globe.

But what exactly is a rotary drilling rig, and how does it function? What components make up this complex machine, and why is it favored over other drilling methods in modern energy and mining operations?

This article provides an accessible yet comprehensive overview of rotary drilling rigs. From basic working principles to core structural components, and from drilling fluids to safety systems, we’ll walk through the essential knowledge needed to understand how these powerful rigs operate in some of the world's most demanding environments.

What is a Rotary Drilling Rig?

Many people new to the industry do not fully grasp what makes a rotary rig different. I often help clients understand its core purpose.

A rotary drilling rig is a mechanical system designed to drill holes into the earth by continuous rotation of a sharp cutting tool called a drill bit. This bit cuts and grinds the rock or soil as it turns, creating a borehole.

It is important to me that you understand the basic idea behind these powerful machines. Rotary drilling is the most common drilling method worldwide. It uses a rotating motion to break up rock and soil. The broken material, called cuttings, is then lifted to the surface. This happens through the circulation of drilling fluid, often called "mud," or compressed air. The fluid also cools the drill bit and stabilizes the borehole walls. My experience shows that this method is very efficient for drilling deep holes in many different types of ground. We have delivered many of these rigs to clients in Africa and the Middle East, where they perform reliably in diverse conditions, from soft soil to hard rock formations. The core principle is simple: turn the bit, push it down, and clear the hole. This process allows for fast penetration and controlled drilling, which is why it is preferred for many projects like installing water wells for communities or exploring for valuable minerals. Understanding this basic function helps clients see why these machines are a smart investment.

How Does a Rotary Drilling Rig Work?

I have often watched drilling crews operate these machines. It might look complex, but the process is quite logical once you know the steps.

A rotary drilling rig works by rotating a drill string, which applies downward pressure to a drill bit that grinds the earth. Drilling fluid or air is pumped down the drill string to cool the bit, carry cuttings to the surface, and stabilize the borehole.

The working process of a rotary drilling rig involves several connected actions. First, the power unit, usually a diesel engine, drives the hydraulic system or mechanical components. This power moves the rotary table or top drive, which spins the drill pipe. The drill pipe is a series of interconnected steel tubes that transmit the rotation and weight to the drill bit at the bottom of the hole. As the bit rotates, it cuts into the ground. At the same time, a pump sends drilling fluid, such as water or a special mud mixture, down through the hollow drill pipes. This fluid exits through nozzles in the drill bit. It then flows back up the annulus, which is the space between the drill pipe and the borehole wall, carrying the rock cuttings with it. This circulating fluid also cools the drill bit, preventing it from overheating, and helps to stabilize the borehole walls, stopping them from collapsing. On top of this, the hoist system raises and lowers the drill string, adding new sections of pipe as the hole gets deeper. This careful balance of rotation, downward pressure, and fluid circulation allows the rig to create deep, clean holes. It is a precise dance between power, pressure, and fluid management.

What Are the Core Components of a Rotary Drilling Rig?

When I first started in this business, I learned that knowing each part of the rig is key. It helps diagnose problems and ensures smooth operation.

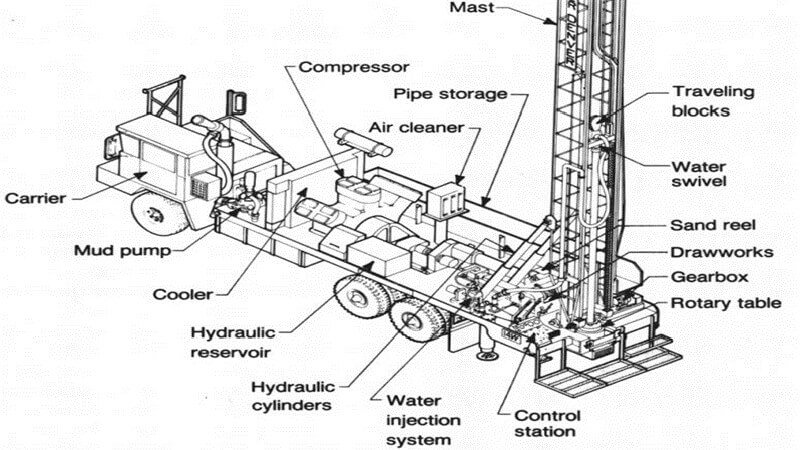

A rotary drilling rig consists of essential parts like the drill bit, drill string, rotary system (table or top drive), mud pump, hoisting system (drawworks and derrick), and power unit. Each component plays a vital role in the drilling process.

Understanding the core components is crucial for anyone working with or purchasing a rotary drilling rig. Each part has a specific job and works with others.

Key Components and Functions:

| Component | Function |

|---|---|

| Derrick/Mast | The tower structure that supports the drill string and hoisting system. |

| Drawworks | The hoisting mechanism that raises and lowers the drill string. |

| Rotary Table / Top Drive | Provides rotational power to the drill string. |

| Drill String | Composed of drill pipe, drill collars, and the drill bit. Transmits force and rotation. |

| Drill Bit | The cutting tool at the bottom of the drill string that grinds rock. |

| Mud Pump | Circulates drilling fluid down the drill string and up the annulus. |

| Mud System | Tanks, shakers, and pumps to prepare, clean, and store drilling fluid. |

| Power Unit | Engine (diesel or electric) that provides power for all rig operations. |

| Blowout Preventer (BOP) | Safety device to control well pressure during drilling (for oil/gas rigs). |

My team and I always emphasize these components when training our clients. For example, a robust mast is essential for supporting heavy drill strings in deep water well projects, while a high-capacity mud pump is non-negotiable for efficient cutting removal in geotechnical drilling. We customize our rigs to ensure these core parts meet the specific demands of each client's project, whether it is for a large foundation project or a detailed mineral exploration. Each part must work perfectly together to achieve the drilling goal safely and efficiently.

What Are the Different Types of Rotary Drilling Rigs?

Customers often ask me which rig is best for them. The answer always depends on the type of work they do and where they do it.

Rotary drilling rigs come in various types, including truck-mounted, crawler-mounted, trailer-mounted, and specialized offshore rigs. Each type is designed for different terrains, mobility needs, and project scales, from small water wells to large oil and gas operations.

The diverse range of rotary drilling rigs means there's a machine for almost every drilling task.

Common Types of Rotary Drilling Rigs:

- Truck-Mounted Rigs: These rigs are built onto the chassis of a heavy-duty truck. They are highly mobile and can quickly move between job sites on roads. This makes them ideal for water well drilling, shallow geotechnical investigations, and small exploration projects where quick setup and relocation are important. My clients often choose these for rural water supply projects where they need to cover large areas.

- Crawler-Mounted Rigs: These rigs are built on a track system, like a tank. They are slower on roads but excel in rough, uneven, or soft terrain. They are often used for mineral exploration in remote areas, geotechnical drilling on difficult sites, and some foundation drilling. Their stability on slopes is a big advantage.

- Trailer-Mounted Rigs: These rigs are pulled by a separate truck. They offer good mobility on roads and can be detached from the prime mover for drilling, which sometimes frees up the truck for other tasks. They are commonly used for mid-size water well and geotechnical projects.

- Skid-Mounted Rigs: These rigs are designed to be stationary or moved by crane or bulldozer within a site. They are not self-propelled. They are typically used for large, long-term projects like oil and gas drilling, large diameter foundation drilling, or continuous mineral production.

- Offshore Rigs: These are very large, specialized rigs used for drilling in oceans or large bodies of water. They include platforms, drillships, and jack-up rigs. They are built to withstand harsh marine environments and drill to extreme depths for oil and gas.

Each type is designed with specific strengths to meet different operational demands. Choosing the right type is critical for project success and cost-effectiveness.

What Industries Use Rotary Drilling Rigs?

I've seen our rotary rigs deployed in many different fields. Their flexibility makes them essential tools across a wide range of industries.

Rotary drilling rigs are used in various industries, including water well drilling, geotechnical engineering, mineral exploration, oil and gas extraction, and civil construction. Their versatility allows them to serve diverse purposes from providing clean water to locating valuable resources.

The widespread use of rotary drilling rigs highlights their adaptability and efficiency.

Industries and Their Uses:

- Water Well Drilling: This is one of the most common applications. Rotary rigs drill boreholes to access underground water sources for drinking, irrigation, and industrial use. Many of our clients in Africa and the Middle East rely on our water well rigs to bring essential water to communities and farms.

- Geotechnical Engineering: Rotary rigs are used to drill boreholes for site investigations. This helps engineers understand soil and rock conditions before building roads, bridges, or high-rise buildings. This data is crucial for safe and stable construction.

- Mineral Exploration: Mining companies use rotary rigs to drill core samples from the ground. These samples help geologists find and assess deposits of minerals like gold, copper, or iron ore. This is a key step in deciding if a mining project is viable.

- Oil and Gas Extraction: Large rotary rigs, especially offshore ones, are used to drill deep wells to reach underground reservoirs of crude oil and natural gas. These operations are complex and require powerful, specialized rigs.

- Civil Construction: Rotary rigs are used for various construction tasks, such as drilling holes for piling, foundations, and ground stabilization. For example, large diameter foundation drilling rigs are essential for skyscraper construction.

- Geothermal Energy: Rotary rigs can drill wells to tap into the earth's heat for geothermal power generation or heating systems. This is a growing area for clean energy.

My company, Hardrock, focuses on providing robust and adaptable rotary rigs that serve these diverse sectors. We understand that each industry has specific demands, and we build our machines to meet those challenges, ensuring top performance whether for a water supply project or a complex geotechnical investigation.

What Are the Pros and Cons of Rotary Drilling?

Every drilling method has its strong points and weak points. I always tell my clients to weigh these carefully before making a decision.

Rotary drilling offers advantages like high speed, versatility across various ground conditions, and the ability to achieve significant depths. However, it can have disadvantages such as high equipment costs, considerable water requirements, and the need for skilled operators.

It's important to have a balanced view of rotary drilling.

Advantages of Rotary Drilling:

- Speed and Efficiency: Rotary rigs can drill very quickly in many types of ground, making them efficient for large projects. This speed means projects can finish faster, saving time and money. I have seen our rigs drill hundreds of meters in a day in favorable conditions.

- Versatility: They can handle a wide range of geological formations, from soft soils to hard rock, by changing drill bits and drilling fluids. This flexibility means one rig can be used for many different projects.

- Depth Capability: Rotary drilling can reach very deep targets, which is crucial for water wells, oil and gas, and deep mineral exploration. Some of our rigs are designed for depths exceeding 500 meters.

- Hole Quality: The use of drilling fluid helps maintain a stable borehole, reducing the risk of collapse and ensuring a clean hole for casing installation.

Disadvantages of Rotary Drilling:

- High Initial Cost: Rotary drilling rigs and their specialized tools are expensive to buy. This can be a barrier for smaller contractors. However, our B2B model and factory direct pricing help mitigate this for our partners.

- Operating Costs: They consume significant amounts of fuel, water (for drilling fluid), and require frequent replacement of drill bits, adding to operational expenses.

- Environmental Impact: The use of drilling fluids can create waste that needs proper disposal. Noise pollution can also be a concern in populated areas.

- Skilled Labor: Operating and maintaining rotary rigs requires highly trained personnel. Finding qualified operators and technicians can be challenging. We often provide training support to our clients to address this.

- Water Requirements: Many rotary drilling methods, especially those using mud, need a large water supply on site. This can be an issue in dry regions.

We help our clients weigh these factors to select the best rig for their specific needs, always aiming for the most effective and practical solution.

Conclusion

Choosing the right rotary drilling rig is key to project success. Understand its parts and how it works to boost efficiency and safety.